Evaluation Quality of One Layer Flat Bread Supplemented with Beans and Sorghum Baked on Hot Metal Surface ()

1. Introduction

Flat bread is as old as civilization. It is eaten with almost every meal in the Middle East, North Africa and Central Asia. Flat breads are often served freshly baked and produced in both the home and bakeries. Flat bread is simple bread made from flattened dough of flour, water, salt, yeast and other optional ingredients. The manufacture of flat bread necessitates special characteristics in flour and dough. Additional (optional) ingredients may be used for processing aids which are essential in particular in the bread-making process, in improving the quality and for fortification of bread to have more nutritive value. Milk, eggs, other cereals, legumes, dates or date syrup, dried fruits, leafy vegetables, cassava, green banana, flaxseed flour, sesame, black seeds, species, meat, and dried or fresh herbs might be added to the formula of the bread [1] .

Legumes have been known as “a poor man’s meat”. They supply protein, complex carbohydrates, fiber and essential vitamins and minerals to the diet, which are low in fat and sodium and contain no cholesterol [2] . Addition of legume and beans to cereal based products could be a good option for increasing the intake of legumes and beans. In addition, legume proteins are rich in lysine and deficient in sulphur containing amino acids, whereas cereal proteins are deficient in lysine, but have adequate amounts of sulphur amino acids. Therefore, the combination of grain with legume proteins would provide better overall essential amino acid balance, helping to overcome the world protein calorie malnutrition problem [3] .

Traditional treatments such as soaking, cooking, germinating and fermenting have been used to improve nutritional quality of the legume [4] - [6] . Food processing technologies can contribute the alleviation of micronutrient deficiencies [7] [8] . Process operations that reduce the level of antinutritional factors and that minimize the losses of micronutrients are of interest. Mechanical, thermal or biological processes have the potential to improve the nutrient availability in foods [8] .

Sorghum (Sorghum bicolor L. Moench) is the king of cereals and is one of the important food crops in dry lands of tropical Africa, India and China [9] . The nutrient composition of sorghum indicates that it is a good source of energy, proteins, carbohydrates, oils, polyunsaturated fatty acid (PUFA), vitamins and minerals [10] - [12] . The most common products are leavened and unleavened breads, porridges, boiled grains and steam cooked products such as couscous [13] . A blend of wheat flour and sorghum flour baked products like muffins, bread and cakes can be produced [14] .

Compositing wheat flour with locally available cereals and root crops has been reported to be desirable [15] . It also encourages the agricultural sector and focused on the use of composite flour for bread and baked products in many wheat importing countries within the last two and half decades [16] [17] .

The objective of this study was designed to replacement of wheat flour with different mixtures such as beans and sorghum flour to produce one layer flat bread and improve the qualities of this type of bread.

2. Materials and Methods

2.1. Materials

Wheat flour (72% extraction rate) and baking ingredients were obtained from local markets. White sorghum (Dorado variety) and beans (Nebraska variety) dried samples were obtained from the Agricultural Research Center, Giza, Egypt. Chemicals were of the analytical reagent grade.

2.1.1. Preparation of Samples

The beans and sorghum samples were carefully cleaned and freed from broken grains and extraneous matter. Beans were soaked in water for 3 h. At the end of soaking period, the soaked water was discarded. The beans were dried in drying oven at 45˚C ± 5˚C. The dried soaked beans were milled to obtain fine flour (315 micron) and kept for flat bread preparation. Sorghum grains were conditioned to 14% moisture content for 16 h and milled by using fractionation Laboratory mill (Brabender Duisburg roller mill, Germany) to obtain fine flour (315 micron).

2.1.2. Dough Rheological Properties

The dough rheological properties of different wheat dough blends with beans or sorghum (5%, 10% and 15%) were examined (after pre-experiments to choose the suitable percentage) with the Brabender Farinograph and Brabender Extensograph according to the constant flour weight procedure [18] .

2.1.3. Flat Bread Preparation

Flat bread was prepared according to the method described by Shobha et al. [9] . Flat bread was contained three different concentrations of beans or sorghum flour (5%, 10% and 15%) as partial replacement for wheat flour (72% extraction rate). Formula consisted of 100 g of flour, 7 g corn oil, 1 g salt and 50 - 54 ml water as mentioned in Table 1. Flour and other ingredients were mixed and then kneaded nicely to make soft dough of uniform consistency. The dough was well kneaded, divided into small balls (50 g), flattened on a hard wooden surface sprinkled with a small quantity of flour. Dough was baked on both sides on a hot pan over low flame, drizzled the griddle with a little oil and cooked slowly for 1 to 2 minutes per side. The prepared breads were then packed in polyethylene bags and stored at −20˚C until further analysis (one layer flat bread pictures at different blends were shown in Figure 1).

![]()

Table 1. Formulas of flat bread with different blends (g/100g).

Formula 1: Wheat control, Formula 2: Beans 5%, Formula 3: Beans 10%, Formula 4: Beans 15%, Formula 5: Sorghum flour 5%, Formula 6: Sorghum flour 10%, Formula 7: Sorghum flour 15%.

2.1.4. Evaluation of Bread

Bread samples were dried at 45˚C ± 5˚C and milled for further analysis i.e. staling, functional properties, chemical analysis.

1) Chemical Analysis

Moisture, protein, fats, crude fiber and ash contents of the raw materials and bread samples were determined according to the methods of AOAC [19] . Total carbohydrate was calculated by difference.

2) Determination of Minerals

Bread sample (2 g) was weighed and heated at 550˚C. Then the ashes were dissolved with 100 ml 1 M HCl. Dissolved ash was analyzed for zinc, iron and calcium contents by using methods of AOAC [19] . Perkin Elmer (Model 3300, USA) Atomic Absorption Spectrophotometer was used to determine these minerals.

3) Organoleptic Evaluation of Flat Bread

Flat bread samples were organolyptically evaluated for its sensory characteristics. Half slice of each bread sample was served for ten panelists on white, odourless and disposable plates. Samples were scored for, taste, chewing ability, texture, aroma and color using a score from 1 to10. The evaluation was carried out according to the method of Land and Shepherd [20] .

4) Alkaline Water Retention Capacity during Storage

Alkaline water retention capacity (AWRC) values of breads were measured after 24, 48 and 72 h of bread storage at −20˚C according to Yamazaki [21] and modified by Kitterman and Rubenthaler [22] .

5) Functional Properties of Bread

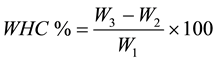

Water holding capacity (WHC) was performed according to the method of Beuchat [23] . Two grammas of each milled sample (W1) were weighed into a pre-weighed centrifuge tube (W2) and 20 ml of distilled water were added. Samples were vortexed and allowed to stand for 30 min at 25˚C ± 2˚C before being centrifuged at 4000 g for 25 min. Excess water was decanted by inverting the tubes over absorbent paper and samples were allowed to drain and reweighed (W3). The percentage of water holding capacity were calculated as:

2.1.6. Statistic Analysis

For the analytical data, mean values and standard deviation are reported. The data obtained were subjected to one-way analysis of variance (ANOVA) at P < 0.05.

3. Results and Discussion

3.1. Dough Rheological Properties

Table 2 exhibits the rheological properties of dough at different blends. Data in Table 2 showed that water absorption was varied from 57.0% to 65.60% of dough at different blends. Differences in water absorption of control, 5%, 10% and 15% for each beans and sorghum flour due to the different protein contents. Flour that is used for flat bread production has optimum water absorption of varying between 38% and 85% [24] . Water is a basic component that helps to get a homogenic mixture of other components in dough, and providing it with a desired viscoelastic structure as well as very effective on final product quality. Water as a dissolving agent for many

![]()

Table 2. Farinograph and extensograph of flour with different blends.

*P.N = Proportional number. Values are mean of three replicates ± SD, number in the same column followed by the same letter are not significantly different at 0.05 level.

organic or inorganic substances is a substance that helps dissolving hydrophilic components such as salt, sugar and insoluble proteins and forms gluten by hydrating in- soluble proteins in water [25] .

Results are in agreements with Deshpande et al. [26] and Morales-de-Le’on et al. [27] whom found that water absorption was increased by addition of bean flour as a result of increased rate of substitution. Substituting wheat flour with 15% bean flour resulted in increases in water absorption of 3% - 5%. Several studies also reported that the dough made from composite flour absorbed more water than that made from wheat flour alone [28] [29] .

Dough stability decreased from 6.50 to 3.50 min for bean blends and from 1.50 to 0.75 min for sorghum blends as the same as increasing addition. Deshpande et al. [26] found that dough stability decreased abruptly as bean flour was added. This is logical since beans are absent of proteins that give wheat dough its viscoelastic properties.

Softening gradually increased with increasing the levels of addition from 45 to 60 B.U for bean blends and from 45 to 100 B.U for sorghum blends. Addition of 15% sorghum had the highest degree of softening compared with wheat control and beans mixtures.

From Table 2, it could be noticed that addition of beans or sorghum to wheat flour at different levels decreased the extensibility, elasticity and the energy of produced dough and the reduction was increased with increasing the level of substitution. In contrast, addition of beans or sorghum to wheat flour increased the proportional number (P.N) of dough of the produced dough from 3.25 to 3.62 and from 1.80 to 2.90 for beans and sorghum dough, respectively.

The water absorption and extensibility of wheat dough decreased on addition of sorghum flour and it also resulted in lesser loaf volume and weight of bread [30] . The addition of wheat flour to sorghum flour improved the dough rheological properties [31] [32] . Processing of sorghum flour into products has faced several limitations. Sorghum, being a gluten-free cereal behaves quite differently from wheat and has poor rheological properties in terms of its pliability, and extensibility [33] [34] .

3.2. Chemical Composition

Chemical composition of raw materials was shown in Table 3. Wheat flour contains 11.21 protein, 0.70 ash, 0.44 crude fiber, 1.26 fats and 86.82% total carbohydrate. Sorghum flour contains 10.72 protein, 1.81 ash, 2.04 crude fiber, 1.40 fats and 86.07% total carbohydrate. Whereas bean flour contains 23.71 protein, 4.00 ash, 4.43 crude fiber, 1.30 fats and 70.99% total carbohydrate. The chemical composition is close to Malomo et al. [35] ; Manay Shakuntalan and Shabakshanaswamy [36] and Wani et al. [37] who have reported the chemical composite of wheat, beans and sorghum, respectively.

Table 4 presents chemical composition of unleavened flat bread at different blends. Protein content varied from 9.88% to 10.18% and 9.07% to 9.24% for beans, and sorghum bread, respectively. Protein was significantly higher in bread fortified with beans then sorghum. Legume proteins are rich source of lysine [38] . Therefore, supplementation of sorghum with legumes has been advocated as a way of combating Protein-calorie Malnutrition. Wheat, rice sorghum and legumes were recommended as good ingredients for production of cereal-based baby foods [39] .

The addition of bean flour to wheat flour was expected to increase the protein content of the final product, since legumes generally contain more proteins than cereals [40] . Addition of legume flour on wheat flour baked products improves the essential amino acid balance of such foods [40] - [43] .

![]()

Table 3. Chemical composition of raw materials (% on dwt)*.

*dwt basis = dry weight basis. **TC = Total carbohydrate was calculated by difference. Values are mean of three replicates ± SD, number in the same column followed by the same letter are not significantly different at 0.05 level.

![]()

Table 4. Chemical composition and minerals of flat bread with different blends (on dwt)*.

*dwt basis = dry weight basis. **TC = Total carbohydrate was calculated by difference. Values are mean of three replicates ± SD, number in the same column followed by the same letter are not significantly different at 0.05 level.

Bread supplemented with beans had the highest values in protein, ash and fiber compared with wheat and sorghum bread.

Fats content of unleavened flat bread at different blends was shown in Table 4. Fat content ranged from 3.17 to 3.34% and from 3.40% to 3.57% in beans and sorghum bread, respectively. Bread supplemented with sorghum had the highest values in fat content compared with wheat and beans bread.

3.3. Minerals Content

Table 4 shows minerals content i.e., calcium (Ca), iron (Fe) and zinc (Zn) of unleavened flat bread at different blends. Results indicated that the Fe values of beans and sorghum bread varied from 6.68 to 7.11 mg/100g and from 7.17 to 7.50 mg/100g, respectively. Bread supplemented with sorghum flour had the highest Fe and Zn content compared with beans and wheat bread and the increase was gradually with increasing the addition of sorghum.

From Table 4, it could be noticed that the Ca content was significantly difference in different blends. In general, Ca was higher in beans bread, while it was lower in sorghum and wheat bread. Minerals are vital to the functioning of many body processes. They are critical players in the functioning of the nervous system, other cellular processes, water balance and structural (e.g. skeletal) systems [44] . Inadequate intakes of micronutrients (minerals) have been associated with severe malnutrition, increased disease conditions and mental impairment [45] [46] . Breads contain zinc ranged from 0.77 to 2.0 mg/100g [47] .

3.4. Organoleptic Characteristics

One of the limiting factors for consumer acceptability is the organoleptic properties therefore; taste, chewing ability, texture, aroma and color were performed. Flat bread was prepared with replacement wheat flour (72% ext.) by 5%, 10% and 15% bean or sorghum flour. Results in Table 5 showed that bread produced from beans or sorghum flour had acceptable values of taste comparing with wheat control bread except for addition of 10% and 15% sorghum flour. Chewing ability, texture and aroma scores were non significantly differences compared with wheat control bread. There is a non significant difference between different blends in color compared with wheat control bread except for addition of 10% and 15% sorghum flour. Moreover, colors of beans bread were very close to those in wheat control bread.

The appearance of the bread fortified with 20% soyabean flour with sorghum was superior for texture. The mean comparison of scores of different attributes like texture, flavor, taste, appearance, mouth feel and overall acceptability were recorded and found to be non significant differences with the treatment groups [14] . Flat bread may be prepared from wheat flour with an addition of chickpea, pigeon pea and bean flours to improve the nutritive value, textural and organoleptic properties. Protein efficiency ratio (PER) of supplemented breads was significantly increased. Enrichment of Egyptian balady bread with decorticated cracked broad bean flour (Vicia faba) increases the essential amino acids and the PER was found to be significantly greater [48] . Improvements

![]()

Table 5. Sensory evaluation of flat bread with different blends.

Values are mean of ten replicates ±SD, number in the same column followed by the same letter are not significantly different at 0.05 level.

of flat bread quality and keeping quality are essential. Automation of flat bread making must be increased [1] .

3.5. Alkaline Water Retention Capacity during Storage

Alkalin water retention capacity (AWRC) of the flat bread was taken as indication on staling degree and freshness. It was determined at different periods; zero time and after storage periods (24, 48 and 72 h) as shown in Table 6. From results, it could be noticed that alkalin water retention capacity of beans and sorghum bread at zero time was lower than wheat bread (280.46% - 287.30% and 250.51% - 263.24%, respectively). Freshness of all flat bread blends was decreased at different periods as well as bread control compared with zero time period. Shaikh et al. [49] found that the rate of bread staling at refrigerated temperature is less as compared to that at (29˚C ± 1˚C) storage. Freshly baked flat breads are soft and elastic. When kept at room temperature they stale within few hours and become hard and tough. For example; chapatis are generally prepared twice a day for lunch and dinner, and unless eaten immediately after preparation, they stale rapidly and become difficult to chew [50] . The staling of large scale manufactured chapatis may become a critical factor consideration [51] .

![]()

Table 6. Alkaline water retention capacity during storage of flat bread with different blends (%).

Values are mean of three replicates ± SD, number in the same column followed by the same letter are not significantly different at 0.05 level.

3.6. Water Holding Capacity

Table 7 exhibits water holding capacity (WHC) of unleavened flat bread at different blends. Data showed that WHC ranged from 223.33% to 233.43% and 218.77% to 223.18% for beans and sorghum bread, respectively. WHC were significantly increased in all samples compared with wheat bread (control). Supplementation of bread with 15% beans recorded the highest value in WHC. Sultan [52] reported that the water absorption is due to increase in quality of flour mixture which also ensures the retention of moisture during dough processing for baked products. Vegetable fibers show practical properties including water holding capacity, swell capacity,

![]()

Table 7. Water holding capacity (WHC) of flat bread with different blends (%)*.

*WHC = water holding capacity. Values are mean of three replicates ± SD, number in the same column followed by the same letter are not significantly different at 0.05 level.

increased viscosity or gelation, ability to bond to biliary acids and cationic exchange capacity which all have significant role in physiological functions [53] . These are due to their porous network structure formed by polysaccharide chains which may hold high amount of water through hydrogen bond [54] , or water may be hold in capillary structures of fibers through surface absorption [55] .

4. Conclusion

From results it could be concluded that protein affected dough rheological parameters and bread staling. Bread supplemented with beans had the highest values in protein, ash, fiber and Ca compared with wheat and sorghum bread. Bread supplemented with sorghum had the highest values in fat, Fe and Zn content. Bread produced from beans or sorghum flour had acceptable sensory properties. Freshness of all flat bread blends was decreased at different periods as well as bread control compared with zero time period. WHC was significantly increased in all samples compared with wheat bread. Supplementation of bread with 15% beans recorded the highest value in WHC. The most suitable addition was the beans addition. Substitution of wheat flour with 15% beans flour could be considered the best addition because all the sensory quality characteristics of the breads were the same as control. Bean is the reasonable source of quality protein available from the household food stuffs.

Acknowledgements

Authors would like to thank the Food Technology Research Institute, Agricultural Research Center for ongoing collaboration to support research and that provided facilities necessary to accomplish the desired goals of research.

NOTES

*Corresponding author.