Optimizing a Single-Absorption-Layer Thin-Film Solar Cell1 Model to Achieve 31% Efficiency ()

1. Introduction

The renowned British mathematician George Box once quipped, “Essentially, all models are wrong, but some are useful” [1]. Generalizations, mathematical processes and other factors prevent models from perfectly representing solar cell behavior; however, simulation can be useful to investigate various design alternatives before a prototype is built. Our previous work [2] showed that a high- level of confidence can be attained for a given model by carefully accounting for key design parameters, benchmarking model behavior to experimental results, and making single-variable adjustments to predict new behavior.

At the time of this publication, power conversion efficiency η for a single-ab- sorption-layer (i.e. single p-n junction) solar cell remains at 28.8%: well below the ~33.5% theoretical limit [3] [4]. Since silicon cell η is restricted to approximately 26% due to intrinsic losses, research has focused mainly on direct bandgap, III-V compounds such as Gallium-Arsenide (GaAs) to approach theoretical efficiency. To this end, [5] [6] [7] demonstrate that strong internal and external luminescence promoted by good optical characteristics is important to high-ef- ficiency (HE) operation for thin-film cells. Hence, improved optical performance has become a dominant theme for thin-film cell design as absorption layer thickness approaches sub-wavelength dimensions.

1.1. Previous Research

The authors’ previous research [2] developed the novel structure shown in Figure 1(a) to simulate a HE GaAs cell from [4] [8] [9]. Though not a perfect representation, the model was useful for examining various design parameters. Extensive research was conducted to ensure that the simulation accurately reproduced experimental results before the GaAs Back-surface Alternating-Contact (GaAs- BAC) cell shown in Figure 1(b) was derived. All variables were held constant for

![]() (a)

(a)![]() (b)

(b)

Figure 1.(a) 3D model of the HE GaAs cell from [4] [8] [9]. (b) 3D model of the GaAs-BAC cell from [2].

the new design while only the emitter and associates electrical contacts were moved to the back-surface. The small, but significant design change improved optical and electrical performance such that model η improved from 28.8% to 30.3%; open-circuit voltage VOC improved from 1.12 V to 1.13 V; short-circuit current density JSC improved from 29.7 mA/cm2 to 30.1 mA/cm2; and FF improved from 86.5% to 88.8%. To further improve cell η, the emitter was removed from the GaAs-BAC cell model to produce the novel design shown in Figure 2(a). FF and η improved slightly to produce the output characteristics shown in Figure 2(b).

1.2. Purpose and Approach

The purpose of this research is to optimize the thin-film GaAs-EBAC cell model from [2] in order to further approach theoretical η. We again utilize Silvaco® ATLAS software to alter design variables, predict electrical characteristics, and simulate the transport of charge carriers through the cell structure [10]. This research represents the final stage before prototype development.

![]() (a)

(a)![]() (b)

(b)

Figure 2. (a) 3D model of the GaAs-EBAC cell from [2]. (b) J-V curves and output parameters of the HE GaAs cell from [4] and the GaAs-EBAC cell from [2].

2. Optimizing the GaAs-EBAC Cell Model

In this section we examine the impact of back-surface reflectivity, absorption layer thickness and absorption layer doping concentration on cell η in order to optimize performance under Air-Mass 1.5 Global (AM1.5G) and AM0 solar spectrums.

2.1. Optimizing the GaAs-EBAC Cell for Terrestrial Application

GaAs-EBAC cell terrestrial performance is simulated at 300˚K under an AM1.5G solar spectrum. Back-surface reflectivity, absorption layer thickness and absorption layer doping concentration are varied to examine impacts on model performance and maximize η.

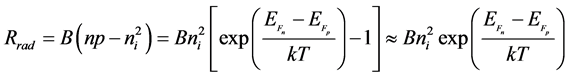

Reflectivity of the bottom contacts contributes directly to photon recycling, which contributes to a higher effective minority carrier lifetime [5] [6] [7] [8] [9]. Radiative recombination is modeled in ATLAS as

, (1)

, (1)

where B is the intrinsic radiative recombination coefficient, EFn - EFp is the energy difference between electron-hole-pair (EHP) quasi-Fermi levels, k is Boltz- mann’s constant, and T is the operating temperature. When reflectivity is varied from 90% to 99%, the model indicates a positive correlation with JSC and VOC, and no correlation with FF as shown in Table 1.

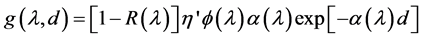

Absorption layer thickness contributes to EHP generation in the cell. Maximum thickness should not exceed minority carrier diffusion length in order to ensure carrier capture at the electrical contacts. Spectral generation rate g is defined as

![]()

Table 1. Design variable impact on GaAs-EBAC cell output parameters under AM1.5G at 300˚K.

*Baseline design parameter setting.

, (2)

, (2)

where R is the front-surface reflectivity, λ is the spectral wavelength, η' is the internal quantum efficiency, ϕ is the photon flux, d is the depth (thickness) of the cell and α is the absorption coefficient. When absorption layer thickness is varied from 1 μm to 1.6 μm, the model indicates a positive correlation with JSC and a negative correlation with VOC and FF as shown in Table 1.

Absorption layer doping is the intentional distribution of impurities within a semiconductor’s crystal lattice to increase the density of majority carriers-either electrons or holes. Increased doping generally improves VOC (i.e. the splitting of quasi-Fermi levels) in non-degenerately doped materials and negatively impacts- minority carrier mobility and lifetime; therefore, optimization is required. When doping is varied from 2 × 1017 cm−3 to 2 × 1018 cm−3, the model indicates a positive correlation with VOC and FF, and a negative correlation with JSC as shown in Table 1.

Complex cell designs often require innovative methods (i.e. genetic algorithms, Monte-Carlo simulation, etc.) to optimize the design; however, the simplicity of the GaAs-EBAC cell model permits an iterative approach to achieve the best design variable combination and minimize the risk of converging on a local maximum. Optimization produces a maximum η of 31% when back-sur- face reflectivity ≈ 99%, absorption layer thickness ≈ 1.2 μm and doping concentration ≈ 8 × 1017 cm−3. Decreasing back-surface reflectivity to a conservative value of 96% reduces η only slightly to 30.9%.

2.2. Optimizing the GaAs-EBAC Cell for Space Application

GaAs-EBAC cell space performance is simulated at 350˚K under an AM0 solar spectrum. The design is well-suited for space operation due to the intrinsic radiation hardness of GaAs [11]; the superior temperature coefficient of GaAs (as compared to silicon) [12] [13] [14]; the high packing density of the back-contact design (W/m2) [15]; and the high power density (W/kg) of HE thin-film cells [16].

Design parameters from section 2.1 are varied again with results shown in Table 2. Optimization produces a maximum η of 25% when back-surface reflectivity ≈ 99%, absorption layer thickness ≈ 1.0 μm and doping concentration ≈ 8 × 1017 cm−3. Decreasing back-surface reflectivity to 96% reduces η slightly to 24.9%. The lower η under the AM0 spectrum (compared to AM1.5G) is attributed to high temperature operation which has a negative impact on VOC: ap- proximately −1.4 mV/˚K [13]. A temperature coefficient adjustment was calculated for a HE triple-junction cell using the manufacturer’s specification sheet [17], which yielded η of 26.8% at 350˚K under an AM0 spectrum. Thus, our model indicates that conceding just 1.8% η can dramatically reduce design complexity, which could improve system reliability and decrease manufacturing cost.

3. Conclusion and Future Work

In this work, parameters were optimized for a GaAs-EBAC cell model [2] in

![]()

Table 2. Design variable impact on GaAs-EBAC cell output parameters under AM0 at 350˚K.

*Baseline design parameter setting.

1Patents pending.

Results suggest that the novel GaAs-EBAC cell design has record-setting potential for terrestrial applications and offers a good alternative to multi-junction cells for space applications. In fact, the model produced η within 1.8% of a leading HE triple-junction cell [17].

Future research will investigate the effects of random texturing on the front- and-back surfaces to exceed 98% photon internal reflection as absorption layer thickness is reduced to less than a spectral wavelength. Additionally, a prototype will be developed to experimentally verify the GaAs-EBAC cell design.

Patent applications have been filed for ideas presented in this paper [18] [19].

NOTES

1Patents pending.