A New Guide Wave Inspection System Using Three Polarized Transverse Wave EMATs without Any Couplant ()

1. Introduction

A lot of pipes have been used for carrying fuel oil, natural gas, etc. for human life, or as a heat exchanger such as a power plant. However, such pipes sometimes break in due to the corrosion or other damages during long range use. It must be avoided for the safety and the efficiency for the human life definitely. Therefore, nondestructive inspection of such pipes is strongly required. As one of the inspection methods, the use of the guide wave has been popular in recent years. The guide wave propagates along the axis direction of a pipe without attenuation of the ultrasonic power. That is, it features the long- range propagation to the axis direction of a pipe, which makes it possible to detect some defects over a broad range [1] - [5] . A lot of features in a guide wave have been researched to use a guide wave effectively [6] . Furthermore, it has been also investigated how to propagate at the curved part of a pipe [7] [8] . Especially, it is observed that a new phenomenon that other guide waves traveling to the circumferential direction can be generated when a guide wave traveling to the axis direction hits at any defects in a pipe [9] . Detective ability has also been investigated by many researchers [10] [11] .

The guide wave inspection system using a polarized transverse wave with a PZT type transducer has already been developed and used in an application field. However, such an ultrasonic sensor requires a couplant with a high viscosity. This makes it difficult to move along the axis direction of a pipe. The inspection system, which can transmit and receive the guided wave using the electromagnetic ultrasonic acoustic wave transducer (EMAT) that injects the polarized traverse waves in the pipe thickness direction, was then developed. Using the developed system, we were able to use the lowest order of the L, T, and F-modes guide waves which are the typical modes of a guided wave travelling into a pipe [12] . However, there has been a question about the first trial inspection system, that is, each guide wave mode might have been driven under different conditions because three EMATs have been placed at the different position on the pipe. The inspection system with the new EMAT to solve this problem has then been developed. The outline of the new system and the experimental results have been shown in the paper.

2. Lowest Order of L, T, F Mode Guide Wave

A guide wave is a type of interference wave of the ultrasonic wave propagating in the pipe axis direction. As shown in Figure 1, for the lowest order mode, they have the following oscillation characteristics in them. That is, for the L-mode, the vibration direction is parallel to the propagation direction. The T-mode operates in the vertical vibration direction to the propagation direction and in a parallel direction to the surface of the pipe. Finally, the F-mode operates in the slant vibration direction to the propagation direction and parallel to the surface [13] . That is, it is postulated that they can have different detecting abilities. We then decided to develop a new pipe inspection system that can alternately use the 3 modes.

3. Fundamental Idea of a Trial Guide Wave Transmitter and Receiver System

The drive principle of a polarized traverse-wave EMAT is shown in Figure 2. It consists

![]()

Figure 2. Non-polarized and polarized transverse wave EMAT.

of a single permanent magnet which applies a magnetic field in the thickness direction and an electromagnetic induction coil which applies an eddy current in the surface direction on the surface of a metal material under the EMAT. A Lorentz force is then generated in the horizontal direction on the surface and to the vertical direction of eddy current direction according to Fleming’s left hand law. The Lorentz force is periodically changed according to the high-frequency vibration of an eddy current on the high frequency electric current in the electromagnetic induction coil. It then converts into a transverse wave. Especially, the vibration is limited to one direction if the direction of the eddy current is in one direction. Such an eddy current can be generated using a rectangular-shaped coil or an ellipse-shaped coil. A transverse wave with any vibration direction can be generated by rotating such an EMAT placed on the metal material in any direction [14] [15] .

Figure 3 shows the basic idea of the trial guide wave-sensor. The polarized transverse wave in any direction can be generated by rotating the polarized transverse EMATs. For the L-mode guide wave, the polarized EMATs, whose polarized direction is parallel to the axis direction, are placed on the surface of a pipe with the same interval in the circumferential direction of the pipe. When these EMATs are driven, the interference

![]()

Figure 3. Three modes guide wave system using polarized EMATs.

in the thickness direction and the circumferential direction can be generated. As a result, an L-mode guide wave may be injected. For the T-mode guide wave, pieces of polarized EMATs, whose polarized direction is vertical to the axis direction, is placed on the surface of a pipe with the same interval to the circumferential direction. For the F-mode guide wave, the polarized EMAT, whose polarized direction is inclined in the axis direction, is placed on the surface of a pipe with the same interval in the circumferential direction. As a result, the F-mode guide wave may be injected. Three rectangle shaped electromagnetic induction coils with different direction are placed at the same position on the surface of the permanent magnet. That is, the system can inspect at high speed using a multichannel pulser and receiver equipment. However, the experimental results using a single pulser and receiver system are indicated on the paper [16] [17] [18] .

4. Guide Wave Generation on the Metal Surface by a Polarized Transverse Wave Propagating to the Thickness Direction Using Two-Dimensional Differential Method

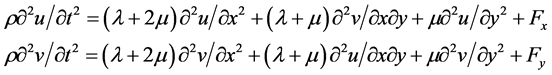

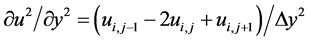

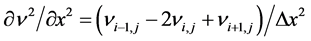

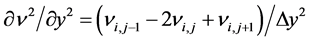

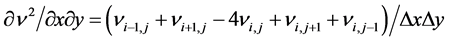

Guided wave generated by using the polarized transverse wave propagating in the vertical direction was confirmed using a two-dimensional difference method. Thin plate model is shown in Figure 4, the mesh space in the thickness direction was divided into 10 pieces and divided into 800 pieces longitudinally. Motion equation used for the difference method is as shown in Equation (1).

(1)

(1)

ρ: Density, λ, μ: Lame constant, u, v: Displacement in x, y directions, Fx, Fy: Drive force for x, y directions

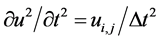

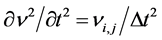

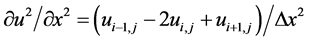

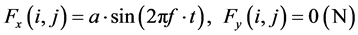

Equations (2)-(9) show the basic equation using the differential method. Fy was assumed as 0 (N) and the Fx was added as sine wave force with two period only 20 meshes at the center position as shown in Equation (9). It is determined that Δx and Δy = 0.2 mm. It was then decided that Δt was 0.02 μs after the trial simulation while changing the Δt.

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

(8)

(8)

i: 1 - 800, j: 1 - 800

(9)

(9)

a: constant (N), i = 291 - 310, j = 1.

As a result, the intensity of the guided wave to arrive at the right end of Figure 4 shows the analysis result while changing the frequency of the driving force as shown in Figure 5. It is confirmed that the guide waves using polarized shear wave propagating to the thickness direction could be generated and became maximum intensity at the drive frequency of 180 kHz. In other words, the use under the drive frequency 200 kH is, can be presumed to be effective in guided wave generation.

![]()

Figure 4. Simulation condition using 2-dimensional differential method.

![]()

Figure 5. Analysis result by the simulation.

5. Optimization of Unidirectional Polarized Transverse-EMAT

The specification of an electromagnetic induction coil which constitutes the EMAT was evaluated using the thickness signal of a 60 mm thick aluminum block with 100 mm width and 100 mm length. The magnetic flux intensity of the used permanent magnet was 0.45 T. The magnet was the neodymium type with a 20 mm width, 30 mm length, and 20 mm height. Two magnets were used as one pair.

Figure 6 shows the signal intensities using the three optimum electromagnetic induction coils when they piled up on the permanent magnet arranged in the three direction. Although the signal intensity by the upper coil decreased because there is gap of about 0.2 mm due to an insert paper used to insult between the electromagnetic induction coils, every received signal intensity is over S/N. Figure 7 shows the received signal waveform example using the electromagnetic induction coil far side from the aluminum specimen surface and the S/N was over 10.

6. L, T, and F Mode Guided Wave System

The experimental system as shown in Figure 8 consisted of a pulser, which input a high frequency and high power electric current with a burst shape, an amplifier, which amplifies the signal by 80 dB, and selects the drive frequency between 70 kHz to 1 MHz, and an oscilloscope and CPU which observes and evaluates the received signal. Many

![]()

Figure 6. Principle of shear wave vertical EMAT.

![]()

Figure 7. Signal amplitude and the best specification of the coil.

drive conditions were tested in order to obtain a good received signal as the nondestructive inspection using the guide wave system. As an example of the trial experiments in Figure 9, it was determined that it is best to drive the electromagnetic acoustic transducer at a 100 kHz drive frequency. The maximum number of EMATs was optimized at 8 for an aluminum pipe with a 60 mm diameter based on the size of the EMAT. The relationship between the drive frequency and the group velocity of a guide wave for a 2 mm thick aluminum pipe is shown in Figure 10. When the 100 kHz drive frequency was used, it was expected that L (0, 2) was 5230 m/s, T (0, 1) was 3130 m/s, and the F (0, 1) mode was 2780 m/s [5] . The received signals after the adjustment are shown in Figures 11-13. The received signal by T (0, 1) mode was the best.

7. Evaluation of Flaw Detection Ability

In order to evaluate the flaw detection ability using the developed guided wave inspection system for pipes, the circumferential notch in which the angle of 360 degrees to the circumferential direction with depth of 0.5 mm to 1.5 mm, penetration drill holes with diameters from 1 mm to 20 mm, and the 30 degrees-slant notches with depth of 0.5 mm to 1.5 mm were machined as shown in Figure 14.

The results for the circumferential notches with 1.5 mm depth and 0.5 mm depth are shown in Figure 15. Reflection ratio was the biggest in the case of F-mode guide wave, although the reflection signal at the opposite side by T-mode guide wave was the biggest. The results for the drilled hole with 1mm diameter and 5 mm diameter in Figure 16. It was almost same results in the case of the cylindrical notch.

Figure 17 indicated the distance attenuation coefficients in the case of the no-dam- age surface and the wet surface of the pipe. Even if the surface is wet or not, the coefficients by T-mode guide wave was the smallest. Therefore when the system inspect the pipe with more than 10 m, T-mode guide wave will become helpful.

8. Conclusion

Guide waves have been used for the nondestructive inspection of a long pipe because they can travel a long distance along the axis direction of a pipe. However, there are no convenient sensors that can easily transmit and receive guide wave. We then tried to develop a convenient guide wave sensor using an electromagnetic acoustic transducer

![]()

Figure 9. Signal amplitude and drive frequency.

![]()

Figure 14. Outline of a pipe with artificial defects.

![]() (a) (b)

(a) (b)

Figure 15. Signal amplitude and depth of a cylindrical notch. (a) 1.5 mm depth; (b) 0.5 mm depth.

![]() (a) (b)

(a) (b)

Figure 16. Signal amplitude and the diameter of drilled holes. (a) 5 mm diameter; (b) 1 mm diameter.

![]()

Figure 17. Attenuation coefficients under different conditions.

(EMAT). The sensing system consists of 8 transverse wave-EMATs which are located around the pipe at every 45˚. Each EMAT can generate transverse waves which vibrate in one direction. This means that such a system could generate many modes of guide waves if the EMATs are set in different directions on the pipe surface. At first, the best specification of the EMAT was experimentally examined. Next, the guide wave sensor system was fabricated using the optimum set of EMATs. As a conclusion, the system could detect L, T, F-mode guide wave. The performance to detect some defects, drilled holes and notches of different sizes and shapes were then evaluated. The experimental results indicated that each mode has a different performance to detect defects. This means that the best performance could be obtained by combining the 3 guide wave modes.

Acknowledgements

This study was partially supported by a Grant-In-Aid for Scientific Research from the Ministry of Education Culture, Sports, Science and Technology (C26420032).