Gamma Irradiation Effect on the Thermal Stability, Optical and Electrical Properties of Acrylic Acid/ Methyl Methacrylate Copolymer Films ()

1. Introduction

In recent years, radiation is used for polymer processing and modification. The irradiation of polymeric materials with ionizing radiation (e.g. gamma rays, X-rays, accelerated electrons and ion beams) leads to the formation of very reactive intermediates, free radicals, ions and excited states. These intermediates can follow several reaction paths that result in disproportion, hydrogen abstraction, arrangements and/or the formation of new bonds. The main interaction of ionizing radiation with polymers concerns its molecular weight is its ability to induce crosslinking or scission which may results in the formation of a wide range of materials without introducing any chemical initiators and without dissolving the sample. Generally, cross-linking and chain scission occur simultaneously but one of them may dominant over the other [Banford HM et al., 1998; Andrzej G. Chmielewski et al., 2005; Sangita Rajvaidya et al.,2006]. Many industries are based on polymer radiation crosslinking technologies such as wire and cable insulation, applications in rubber tires and radiation vulcanization of rubber latex [Andrzej G. Chmielewski et al., 2005]. Vinyl polymers having hydrogen atom substituents (-H2C-CHR-) n, such as Poly acrylic acid (-H2C-CHCOOH-) n, undergo dominant hemolytic rupture of the C-H bonds to form hydrogen-free radicals which crosslink with each other [R. Mishra et al., 2001]. Other kinds of polymers such as poly methyl methacrylate PMMA (-H2C-C (CH3) COOCH3-) n undergoes dominant main-chain scission and the liberation of -COOCH3 side groups occurs for every main-chain scission as a result of irradiation. [Hiroshi Yoshida et al., 1995].

Acrylic acid/ Methyl methacrylate (AAc/MMA) copolymers are used in wide range of bioapplications such as bioadhesives and drug delivery carriers [Tadaaki Inoue et al., 1998]. Also in technological applications such as light emitting diodes and organic based lasers [R. Sosa Fonseca et al., 2001]. Poly methyl-methacrylate (MMA) has attracted much attention for use as optical components and in opto-electronic devices due to its high transparency, low cost and volume productivity [F. Yakuphanoglu et al., 2007]

In this present study, A series of AAc/MMA copolymer films with comonomer composition of 60/40 respectively was prepared using γ- irradiation induced polymerization. The prepared copolymer films were subsequently irradiated by gamma irradiation over irradiation doses up to 200 kGy. The optical properties and thermal stability of the copolymer were examined by UV-Visible spectroscopic analysis and thermo-gravimetric Analysis (TGA) respectively. Also their electrical properties were studied.

2. Experimental

2.1. Materials

Acrylic acid, (AAc) (Merk, Germany) of purity 99% was used as received, Methyl methacrylate, (MMA) (Merk, Germany) of purity 99% was used as received and Acetone (Aldich, Germany).

2.2. Preparation of AAc/MMA Copolymer Films

A constant amount of AAc and MMA were added to acetone and mixed well using vortex. Copolymerization of AAc with MMA was done by using 60Co g-rays as initiator with dose of 40 kGy at a dose rate of 4.62 kGy/h using a gamma cell available in NCRRT, AEA, Cairo, Egypt. Equal amounts of the produced copolymer solution were poured into a Petri dish (glass) and dried at room temperature for 72 hours.

2.3. Irradiation Process

The films were exposed to gamma radiation from the same 60Co source used in the preparation step. The irradiation process was performed in air at room temperature. The irradiation doses was 5, 10, 25, 30, 50, 100, 150 and 200 kGy with dose rate of 4.62 kGy/h.

2.4. Thermo-Gravimetric Analysis (TGA)

The weight percentage studies versus temperature were performed by using Thermo-gravimetric Analysis (TGA) system of type Perkin Elmer Pyris 6 TGA, Germany. Ten mg of the dried samples were used for the analysis. Temperature was cycled from 30 to 600ºC at a rate of 10ºC/ min in a nitrogen atmosphere where the nitrogen flow was kept at constant rate of about 50 ml/min to prevent thermal oxidation processes of polymer samples.

2.5. UV-Visible Spectroscopic Analysis

Determination of the absorbance spectra of the copolymer films were carried out using JACSO V-560 UV-Vis spectrophotometer, Japan, in wavelength range from 200-900 nm.

2.6. Electric Measurements

The electrical measurements of all films were performed using a locally designed electrical circuit. An air drying type of silver paste was applied to the opposite surfaces of polymer samples in a sandwich configuration to ensure good electrical contacts. For the DC measurements, the samples were placed by a special designed cell in an oven. The temperature of the samples was monitored using a K-type thermocouple attached with digital thermometer type Tri-Sense, Cole – Parmer, USA, with temperature resolution of 0.1oC.The sample temperature was varied within a range of 300 – 400 ˚K. A Keithley digital electrometer of the type 6517 A, USA was used for the determination of the DC resistance of the films. The AC measurements were carried out using the Hioki LCR meter of the type 3531 Z Hi-Tester, Japan, operating at a frequency range (100 Hz–1 MHz), with impedance accuracy ranging from 0.15% up to 4%. The dielectric measurements were performed at room temperature in a frequency range (100 Hz–1 MHz). The LCR meter was connected to the computer through an Rs–232c interface.

3. Results and Discussion

3.1. Thermo-Gravimetric Analysis (TGA)

The thermal stability of the films was tested by TGA technique over a temperature range from room temperature up to 600oC. Figure 1 shows the weight percentage versus temperature of the films.

In Figure 1 AAc shows its four degradation steps at 100, 250, 400, and 450oC which are due to the loss of associated water, anhydride formation, decarboxylation and backbone degradation respectively [A. El-Hag Ali et al, 2003] while MMA was characterized by weight losses at 203 and 380oC which can be attributed to desorption of water and complete decomposition [Erjun Tang et al, 2006; Maria Omastova et al, 1997]. Also it is clear that the thermal stability increases with the irradiation dose up to 100 kGy then it decreases again for doses 150 and 200 kGy. This is maybe due to that irradiation with doses up to 100 kGy increased the degree of crosslinking in the AAc/MMA copolymer films which hindered the flux of degradation. Then for higher doses (150 and 200 kGy)

Figure 1. The weight percentage versus temperature of the AAc/MMA copolymer films.

chain scission started to dominate over crosslinking causing lower thermal stability. [L.C. Lopérgolo et al, 2000; Maria Omastova et al, 1997].

3.2. UV-Visible Spectroscopic Analysis

UV-Vis analysis was performed on the studied samples. The absorbance spectra are shown in Figure 2. It can be noted that the samples which was irradiated with higher doses (100, 150 and 200 kGy) have absorption edges that are shifted towards longer wavelengths.

According to the band theory of solids, the absorption coefficient (a) can be calculated from Urbach rule as:

(1)

(1)

where Io and I (t) are the intensities of the incident and transmitted light, respectively and t is the film thickness. As the absorption coefficient depends on the photon energy (hn), the relation between them can be expressed as:

(2)

(2)

where A is a constant and Eopt is the optical energy gap. Here s represents an index that can take any of the values: 1/2, 3/2, 2 or 3 depending on the type of transition responsible for the absorption.

The simplest way to deduce the type of transition is to examine the value of r, which fits hn to ahn with a

Figure 2. The absorbance spectra of the AAc/MMA copolymer films.

straight line relationship. In our case, s = 1/2 which means an allowed direct transition. The estimated values of the optical band gap of the samples are listed in Table 1.

For more characterization of the optical behavior of AAc/MMA films, the band tail width values were determined using the Urbach rule as:

(3)

(3)

where B is a constant and  is the band tail width. The estimated values of the band tail width of the films are listed in Table 1.

is the band tail width. The estimated values of the band tail width of the films are listed in Table 1.

In Table 1 one can see that the irradiation process has no significant effect on both band gap and the band tail width values from the unirradiated sample to the irradiated up to 50 kGy; however at higher doses 100, 150 and 200 kGy the band gap and band tail width values are decreased compared with those of the lower doses. Those results indicate that irradiation at higher doses 100, 150 and 200 kGy affect the copolymer to crosslink. The crosslinking of the copolymer is caused by the formation of new covalent bonds and therefore new different chains were obtained which in turn hindered the motion of molecules and reduce their activity and, consequently decrease the optical band gap and the band tail width. [H. M. Abdel-Hamid et al, 2005; R. Mishra et al, 2000; F. Sharaf et al, 1995].

3.3. Electric Measurements

3.3.1. DC Measurements

(I-V) characteristics were performed for all prepared films in the range (0-200 V). (I-V) characteristics indicated linear Ohmic behavior. An applied voltage value of 100 V was selected in measuring  and the active-

and the active-

Table 1. The values of optical band gap of allowed direct transitions and band tail width and their correlation coefficients of the AAc/MMA copolymer films.

tion energy of the samples. The values of electrical conductivity  (W-1 m-1) of the samples versus the irradiation doses are shown in Figure 3 and listed in Table 2.

(W-1 m-1) of the samples versus the irradiation doses are shown in Figure 3 and listed in Table 2.

From the obtained results one can notice that the irradiation may induce crosslinking of the AAc/MMA filmswhich in turns reduces the DC conductivity of the samples. It was suggested that the decrease in sDC is due to the formation of some defects in the energy gap as a result of γ- irradiation [R.M. Radwan et al., 2008]. These defects (sometimes called traps or clusters) create barriers against the mobility of charge carriers (electrons) already existing in non-irradiated polymeric materials.

The DC conductivity decreased from 1.61x10-7 of the unirradiated sample to 2.05 x10-10 of that irradiated with 100 kGy by approximately more than three orders of magnitude. At the 150 kGy we can see that the irradiation started to break the branched chains and therefore increased the conductivity until the value 2.23 x10-8 of the 200 kGy has been reached. This result is in agreement with the results obtained from the UV-Visible spectroscopy and TGA analysis.

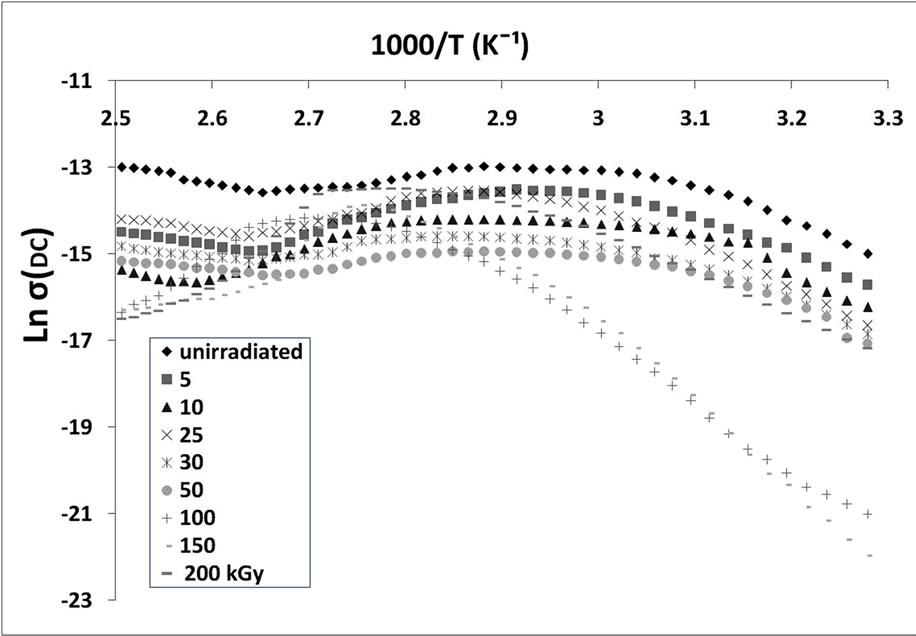

The dependence of the DC conductivity ( ) on temperature (T) for the produced copolymer films was investigated. Figure 4 shows the plot of ln

) on temperature (T) for the produced copolymer films was investigated. Figure 4 shows the plot of ln  (T) vs. 1/T for the copolymer films over a temperature range (300 < T < 400 ˚K). For the proposed temperature range, the conductivity was found to increase with an increase of temperature for all films. For which, it is clear that the plots follow Arrehenius behavior throughout the four regions having four values of activation energy. The values of activation energy

(T) vs. 1/T for the copolymer films over a temperature range (300 < T < 400 ˚K). For the proposed temperature range, the conductivity was found to increase with an increase of temperature for all films. For which, it is clear that the plots follow Arrehenius behavior throughout the four regions having four values of activation energy. The values of activation energy  (eV) of the samples and their correlation coefficients are listed in Table 3.

(eV) of the samples and their correlation coefficients are listed in Table 3.

The DC conductivity ( (T)) values of the films in all areas exhibit the validity of applying Arrhenius equation.

(T)) values of the films in all areas exhibit the validity of applying Arrhenius equation.

(4)

(4)

Figure 3. The DC conductivity (sDC) versus irradiation dose for AAc/MMA copolymer films.

Figure 4. The logarithmic variation of conductivity (DC) versus 1000/T ( ) for the AAc/MMA copolymer films.

) for the AAc/MMA copolymer films.

where  is the temperature independent constant, K is the Boltzmann constant and

is the temperature independent constant, K is the Boltzmann constant and  is the electrical activation energy.

is the electrical activation energy.

All the plots of Figure 4 indicate that the maintenance of four segments obeying the normal Arrhenius equation. It can be seen that the general trend of the conductivity–temperature curves is similar; the curves themselves sometimes overlap and intersect at a relatively higher temperature range [A. Shehap et al, 1998]. From the inspection of this figure, it is clear that the DC conductivity  decreases as the g-dose increases. However, the samples irradiated at 100 and 150 kGy show a higher decrease in

decreases as the g-dose increases. However, the samples irradiated at 100 and 150 kGy show a higher decrease in  when compared with the unirradiated sample and the irradiated films with doses from 5 to 50 kGy. The

when compared with the unirradiated sample and the irradiated films with doses from 5 to 50 kGy. The  of the sample irradiated with 200 kGy is in the same conductivity range of the samples irradiated with lower doses which in agreement with the result of

of the sample irradiated with 200 kGy is in the same conductivity range of the samples irradiated with lower doses which in agreement with the result of  at room temperature.

at room temperature.

From Table 3, the values of the electrical activation

Table 3. The values of activation energy  (eV) of the AAc/MMA copolymer films and their correlation coefficients.

(eV) of the AAc/MMA copolymer films and their correlation coefficients.

energy of the unirradiated AAc/MMA film and the irradiated films with doses from 5 to 50 kGy are in the same range while the activation energies of the films irradiated with 100 and 150 kGy are higher in value than that of those irradiated with lower dose. Then at 200 kGy the activation energies lie in the same range of the lower doses (5-50 kGy). That may be attributed to the fact at 100 and 150 kGy the polymeric structure got morecrosslinked than that of lower doses and therefore need more energy to start electric conduction. At 200 kGy, the irradiation broke some of the crosslinked bond and chain scission started to dominate over crosslinking.

3.4. AC Measurements

Measurements of the dielectric parameters of the samples have also been carried out, and the obtained results were used for evaluation of the dielectric constant (ε') and dielectric loss (ε"), applying the Debye’s equations [R. M. Radwan et al., 2004]:

(5)

(5)

(6)

(6)

where ε’s is the dielectric constant at static field, ε¥’ is the dielectric constant at the end of the frequency range (minimum value of ε’ ) and  and (τ) is the relaxation time. By simple mathematical manipulation, one can get the dielectric parameters in the form of the equation representing a straight line, namely

and (τ) is the relaxation time. By simple mathematical manipulation, one can get the dielectric parameters in the form of the equation representing a straight line, namely

(7a)

(7a)

Equation (7a) is more useful for the higher frequencies [R. M. Radwan et al., 2008], it can be written as

(7b)

(7b)

The relaxation time can be determined from the intercept of the straight line in the equation (7b) which was used in the Debye fitting in equations (5) and (6). Figures 5 and 6 show the variation of the dielectric con-

Figure 5. The variation of the Dielectric constant ( ) with frequency of the AAc/MMA copolymer films.

) with frequency of the AAc/MMA copolymer films.

Figure 6. The variation of the fitted dielectric loss (ε") with frequency for the AAc/MMA copolymer films.

stant (ε`) and dielectric loss (ε") with frequency for the copolymer films within the frequency range 100Hz to 1MHz at room temperature respectively.

From the obtained results one can notice that the dielectric constant and loss increase with dose up to 100 kGy then decrease at doses 150 and 200 kGy. The increase of e` and e" value, due to the irradiation of the polymer in air is attributed to the increase of the number of dipoles in the polymer matrix where may be resulted from the increase of the number of C = O double bonds and C–H bonds in the polymer matrix. On the other hand, the increase of the irradiation does to 150 and 200 kGy may increase the number of free radicals that may react to decrease the number of dipoles in the samples. [R.M. Radwan et al. 2008].

4. Conclusion

The effect of gamma irradiation on AAc/MMA copolymer films has been investigated. The gamma irradiation, up to 100 kGy, leads to crosslinking reaction domination over chain scission causing an increase in the thermal stability of the films and a decrease in the DC conductivity ( ) of the copolymer films; its value falls about three orders of magnitude from its original value. The optical band gap, band tail width and electrical activation values for the sample irradiated with 100 kGy were higher than that of lower doses. Also the values of the dielectric parameters were found to increase with irradiation dose up to 100 kGy. These results indicate that the irradiated copolymer films with dose 100 kGy may be suitable for applications such as cable and wire isolation for electronic systems.

) of the copolymer films; its value falls about three orders of magnitude from its original value. The optical band gap, band tail width and electrical activation values for the sample irradiated with 100 kGy were higher than that of lower doses. Also the values of the dielectric parameters were found to increase with irradiation dose up to 100 kGy. These results indicate that the irradiated copolymer films with dose 100 kGy may be suitable for applications such as cable and wire isolation for electronic systems.