Selection of Thickness of High Density Polyethylene Film for Mulching in Paddy Rice ()

1. Introduction

Rice (Oryza sativa L.) is one of the most important food crops in the world. Half of the world’s population is dependent on rice as a staple food. In Asia, approximately 92% of rice in the world is produced and consumed [1]. In China, there were 31.7 million hectares of rice field, accounting for about 20% of world’s rice area [2]. China produces 35% of world’s total rice production every year.

Rice production consumes large quantity of irrigation water. Bhuiyan [3] estimated that rice consumed about 90% of total irrigation water for all crops. Additionally, rice is the crop that offers has great potential to save irrigation water, because its physiological water requirement (4500 m3·water·ha−1) is much less than its actual water consumption, which is equivalent to that of some upland crops [4,5]. Plastic film mulching, one of water saving management practices for rice production, is developed in 1980s and has been adopted as a new rice cultivation technique in many regions of China [6,7]. Under plastic film mulching management practice, the rice production is based on limited irrigation without constant flooded conditions on soil surface. It is substantially different from both traditional flooded rice cultivation and rain-fed rice cultivation. This can reduce irrigation frequency and amount of water. In recent years, plastic film mulching has been widely applied throughout the world. The total planting with plastic film mulching has reached 100,000 ha [8].

A lot of researches have revealed that plastic film mulching has many advantages, such as moderating soil temperature by insulating the soil surface, conserving soil moisture, preventing leaching of fertilizers, controlling weed growth under mulch film, making maturity earlier and increasing yield [9-13]. High-density polyethylene (HDPE) film is preferred as mulching material for crop production [14].

In plastic mulching, the thickness of mulch film should be in accordance with type and age of crops. Economics suggest that the film thickness should be the minimum possible commensurate with desired life and strength [15]. At the present, there is lack of information about the thickness of plastic-film mulching with non-flooding conditions. Under HDPE film mulching cropping system, the objective of this study is to select the optimal thickness of HDPE film for rice production. Herein, we investigated the effect of various thickness of HDPE film on physiological index of rice, soil parameter and weed control, etc. It is hoped that our study could improve current management strategies in rice production.

2. Materials and Methods

2.1. Experimental Site

The field experiment was carried out in Xinyang City Academy of Agricultural Sciences (XCAAS) (E113˚45'- 115˚55', N30˚23'-32˚27') in Henan Province, China, from April to August 2012. The average annual precipitation is 900 - 1400 mm. The annual mean temperature is 15.1˚C - 15.3˚C, and the effective accumulated temperature of the annual mean temperature is 4386.2˚C - 5247.1˚C·d.

2.2. Experimental Design

Different thickness (5, 10, 15, 20 μm) of high density polyethylene (HDPE) film (6 m × 1.7 m) was paved on each plot before transplanting. The plot without HDPE film was CK. Each treatment was replicated thrice. All plots were arranged in a randomized blocks design, and the plot size was 10.2 m2. Each plot was surrounded by a buffer zone of 0.2 m wide. In the growing season, water layer with 3 - 5 cm depth was maintained in the buffer zone.

The paddy soil, belong to clay, contained 53.3 mg·kg−1 available N, 10.05 mg·kg−1 available P, 74.9 mg·kg−1 available K, 21.4 g·kg−1 organic matter, and its pH was 6.4. Before rice seedlings transplanted to this field, 30.60 kg milk vetch, 0.76 kg compound fertilizer (N:P:K = 16:16:16), and 0.076 kg urea were applied to each plot.

2.3. Seedling Preparation

Hybrid rice (Liang-you 6326) was provided by XCAAS. Seeds were sown on nursery bed on 22 March. One month later, seedlings were transplanted to plots, with the planting density of 0.43 m × 0.35 m and 1 plant per hole.

2.4. Sampling and Measurements

2.4.1. Weeds

Weed number and weed mass were used to evaluate the effects of HDPE film on weed control. One month after transplanting, weed number in each plot was surveyed, with the interval of 20 days, totally 3 times. Once the last survey finished, all weeds were collected to measure fresh mass, and then dried at 70˚C for 2 days to measure dry mass. The formula of weed control effect is as follow:

Weed control effect = (weed number of CK

– weed number of HDPE film mulching)/

weed number of CK × 100.

2.4.2. Soil Temperature

The soil temperature was determined at 2, 5 and 10 cm below ground at various time point (6:00, 8:00, 10:00, 12:00, 14:00, 16:00, 18:00), on 10-July (heading stage), which was a sunny day.

2.4.3. Soil Moisture

Soil samples were collected using wi39701 hard soil sampler (Dongxi instrument technology co., Ltd., Beijing) at 10, 20 and 40 cm below ground on 18, June and 10, July, respectively. Gravimetric moisture for each sample were calculated using the following formula:

Gravimetric moisture

= (fresh mass − dry mass)/(dry mass) × 100.

2.4.4. Photosynthetic Rate

Photosynthetic rate of the second leaf from the top was determined by a LI-6400 portable photosynthesis system analyzer (LI-COR Biosciences, USA). The measurement was conducted at 9:00-11:00 of a sunny day on 26 July (the middle period of grouting) following the method of Liu [16] with 5 duplications for each treatment.

2.4.5. Seedling Biomass

One month after transplanting, 3 rice seedlings were collected in each plot to measure seedling height, tiller, fresh and dry mass, with the interval of 20 days, totally 3 times.

2.4.6. Residue of HDPE Film

After harvest, all films were collected, washed and air dried. HDPE film residues were calculated using the following formula:

Film residue = the mass of HDPE film before paved

– the mass of HDPE film collected.

2.4.7. Rice Yield

Five samples were randomly selected from each plot to measure the kernel number per panicle and thousand kernel mass.

2.5. Data Analysis

Statistical analysis was performed using one way ANOVA for variance analysis, and LSD for multiple comparisons (SPSS 16.0). The means were separated on the basis of least significant differences at the 0.05 probability level.

3. Results and Discussion

3.1. Weed Control

3.1.1. Weed Population and Gross Number

HDPE Film mulching could control weeds in paddy field and be useful for limiting weed communities at low levels and thereby avoiding severe weed outbreaks.

Two main species of weeds (Eleocharis plantagineiformis, Cyperaceae) were found in the HDPE film mulched fields. In addition to these 2 species, other 4 weed species (Echinochloa crusgalli (L.) Beauv, Leptochloa chinensis (L.) Nees, Portulaca oleracea L. and Monochoriavaginalis (Burm.f.) PreslPont) were observed in CK fields.

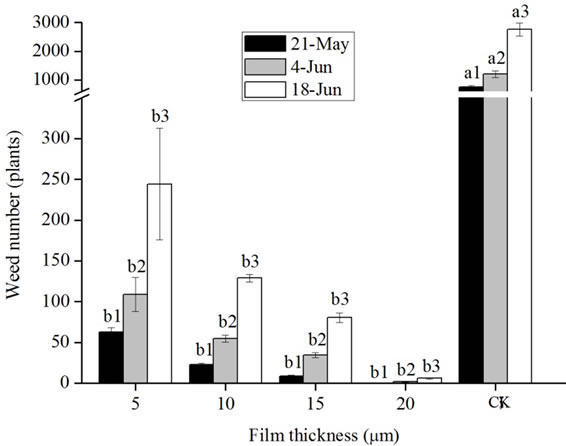

The CK had the greatest total weed number and all treatments recorded significant weed reduction. In all three stages (Figure 1), there was no significant difference on weed number among different thickness of HDPE film, but was remarkably less than CK (P1 < 0.05, F1 = 177.413; P2 < 0.05, F2 = 107.450; P3 < 0.05, F3 = 123.808). In this experiment, the weed control effect of HDPE film mulching was all above 94%. Therefore, the goal of weed control could be achieved by HDPE film mulching even if its thickness is only 5 μm. This result was consistent with the viewpoint of Krish [15] that the film thickness should be the minimum possible.

3.1.2. Weeds Biomass

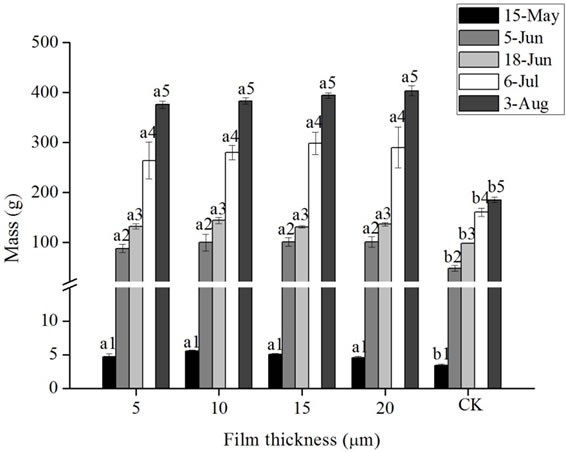

All treatments showed remarkable reduction in fresh and dry mass. These practices could reduce weed mass production, postponing weed undertaken 5 - 6 weeks after rice transplanting. There was no significant difference on fresh and dry weed mass among different thickness of HDPE film, but was remarkably less than CK (Figure 2) (P1 < 0.05, F1 = 136.967; P2 < 0.05, F2 = 262.179).

3.2. Soil Parameter

As an emerging water-saving technology for rice production, plastic film mulching with non-flooding is different from traditional flooded cultivation that maintains as table water layer on soil surface. This cultivation change

Figure 1. Weed numberin plots with different thickness of HDPE film mulching Differentletters on the columns indicate significantly different meansby ANOVA analysis (P < 0.05). The same number subscriptafter lettermeans that the ANOVA performed is in a same group.

Figure 2. Weed mass in plots with different thickness of HDPE film mulching Differentletters on the columns indicate significantly different meansby ANOVA analysis (P < 0.05). The same number subscriptafter lettermeans that the ANOVA performed is in a same group.

resulted in changes of rice growth environment through modification of soil water content and temperature. In the present study, HDPE film mulching increased soil water content and temperature.

3.2.1. Soil Temperature

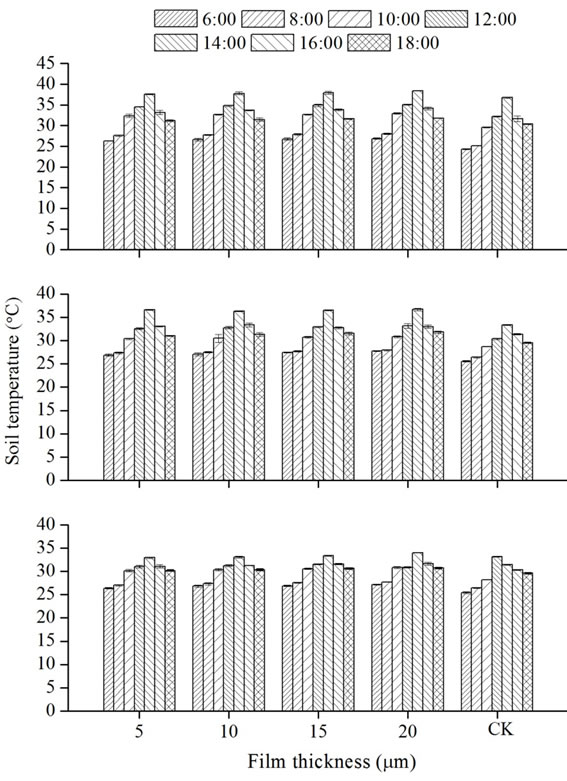

The dynamics of soil temperature at various depths (2, 5, 10 cm) were greatly affected by HDPE film mulching, which could make the soil temperature increased by 0.57˚C - 3.33˚C. The greatest difference in soil temperature appeared at 14:00 during the whole observation, at which time the soil temperature was 0.97˚C, 3.33˚C and 2.60˚C higher than CK, respectively. Soil temperature at various depths (2, 5 and 10 cm) was significantly different to CK in each time point (Figure 3) (P < 0.05). As a whole, the soil temperature of HDPE film mulching in each thickness increased gradually as the increasing of the film thickness, but the significance difference was at the same level.

3.2.2. Soil Moisture

Soil moisture in all HDPE film mulching treatments at 10 cm depth were remarkably higher than CK (P < 0.05, F = 4.39). There was no significant difference existed in all treatments at 20 and 40 cm depth. Soil moisture decreased as the increasing of soil depth (Figure 4).

3.3. Physiological Index of Rice Seedling

3.3.1. Photosynthetic Characteristics of Leaves

Rice leaves are the most important photosynthetic organ, and the yield formation is essentially to the accumulation and distribution processes of photo-synthetic products [17].

Figure 3. Soil temperaturein plots with different thickness of HDPE film mulching Each date perform ANOVA (P < 0.05) independently. Data in tablepresent as mean ± SE.

Figure 4. Soil moisture in plots with different thickness of HDPE film mulching Different letters on the columns indicate significantly different means by ANOVA analysis (P < 0.05). The same number subscript after letter means that the ANOVA performed is in a same group.

All the data in HDPE film mulching treatments were remarkably higher than CK (Table 1) except rice leaf temperature (P1 < 0.05, F1 = 12.779; P2 < 0.05, F2 = 16.386; P3 < 0.05, F3 = 14.396; P4 < 0.05, F4 = 6.478; P5 = 0.561, F5 = 0.783).

During the whole growth period, the leaf net photosynthetic rates and transpiration of the mulching treatments were higher than the CK. These results showed that the mulching cultivation had effectively improved the net photosynthetic rate of rice during the middle period of grouting.

3.3.2. Seedling Parameters

Plant height of rice was either slightly stimulated or inhibited (Figure 5), However, seedling height was not significantly different among treatments (P < 0.05).

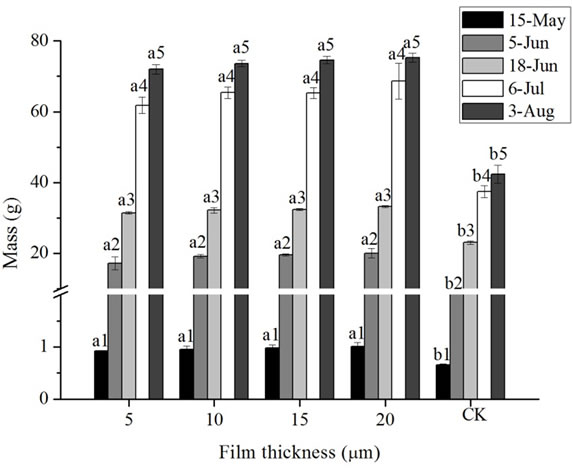

For number of tiller, fresh and dry mass of rice, all treatments promoted tiller growth, fresh and dry mass, but it was not significantly different (Figure 8) (P < 0.05) (Figures 6 and 7) (P < 0.05).

In general, all the data in treatments with HDPE film mulching were higher than CK. The seedling height, tiller, fresh and dry mass in each treatment except CK increased gradually as the increasing of the film thickness, but the significance difference was at the same level.

This part presented a biomass-based parameters of rice, designed to explain effects of different thickness of HDPE film mulching conditions, morphogenesis at the individual seedling height, seedling fresh and dry weight [18]. The organ dimensions of rice were taking corresponding organ biomass as an independent variable. Various variables in rice showed consistency in observation. However, the biomass was considered at the whole plant scale and distributed among plant organs. The plant biomass has shown to be affected by both cultivars and environmental factors [19-21].

Figure 5. Rice seedling heightin plots with different thickness of HDPE film mulching Different letters on the columns indicate significantly different means by ANOVA analysis (P < 0.05). The same number subscript after letter means that the ANOVA performed is in a same group.

Table 1. Photosynthetic parameters of leaves in different HDPE film thickness at the middle grouting stage.

Figure 6. Fresh mass in plots with different thickness of HDPE film mulching Different letters on the columns indicate significantly different means by ANOVA analysis (P < 0.05). The same number subscript after letter means that the ANOVA performed is in a same group.

Figure 7. Dry biomass of seeding as affected by the thickness of HDPE film Different letters on the columns indicate significantly different means by ANOVA analysis (P < 0.05). The same number subscript after letter means that the ANOVA performed is in a same group.

Figure 8. Seedling tillers per hill in plots with different thickness of HDPE film mulching Different letters on the columns indicate significantly different means by ANOVA analysis (P < 0.05). The same number subscript after letter means that the ANOVA performed is in a same group.

3.4. Film Residue

Mulching HDPE film has the effect of increasing temperature and keeping soil moisture, which has brought a positive and important progress in agricultural productivity. Nevertheless, the residue of mulching plastic film in the field has already become a negative factor that affected agricultural environment, which destroyed soil structure and harmed growth of crop [22]. In this study, film residue was remarkably reduced as the increasing of film thickness (Figure 9) (F = 1267.960, P < 0.05).

3.5. Yield and Economic Benefit

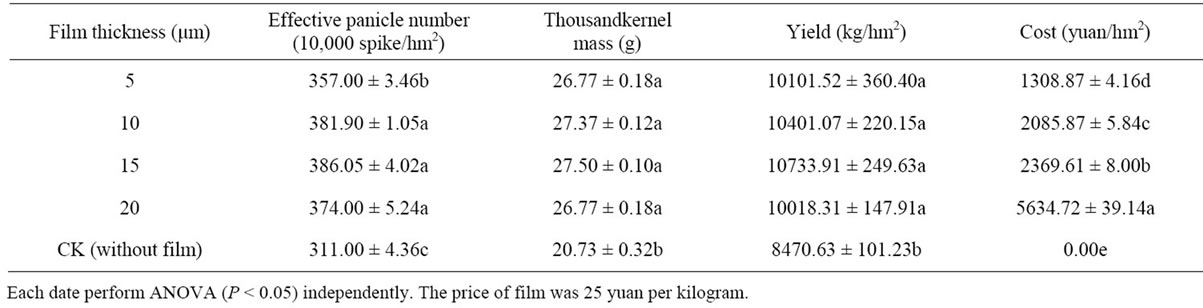

From Table 2, Thousand kernel mass and yield in film mulching treatment was higher than CK (P1 < 0.05, F1 = 218.882; P2 < 0.05, F2 = 13.903). Effective panicle number in the 5 µm film treatment was fewer than that of 10 µm, 15 µm, 20 µm, higher than CK (P < 0.05, F = 62.181). The yield components of rice were significantly optimized under mulching cultivation, a maximum yield

Table 2. Economic benefit in different treatments.

Figure 9. Film residuesin plots with different thickness of HDPE film mulching each date perform ANOVA (P < 0.05) independently.

increase by 21.09% (15 µm) compared with the CK. The plastic film mulching displayed increase trend of the yield compared with CK, and this result was consistent with the report by Shen [9]. Film cost will increase as the increasing of film thickness (P < 0.05, F = 13234.242).

Some reports indicate that plastic mulching has a negative effect on crop growth, with some conditions resulting in yield reduction [23-25]. Nevertheless, our experiment conclusion is on the contrary. The reason for the yield reduction through plastic mulching may be the soil temperature going beyond the optimum during the growing season.

4. Conclusions

Cluster analysis revealed that mulching cultivation could increase soil temperature, preserve moisture, increasing dry matter accumulation and high yield formation of rice [26]. The plastic film mulching displayed increase trend of the yield compared with CK, this experiment as consistent with the report by Shen [9].

Our results proved that the HDPE film thickness of 5 µm could control weeds in rice field effectively. Soil temperature and soil moisture could increase as the film thickness increasing, which could make the rice growth period earlier. Nevertheless, after the analysis of economic effect and film residual, the thicker film is not the best one. There was no difference among 4 film thickness on photosynthetic parameter and biomass. It is further proved that the film thickness of 10 µm could gain the maximum economic effect. Taken together, the HDPE film thickness of 10 µm was the optimal choice for rice production.

But their reports indicate that plastic mulching has a negative effect on crop growth, with some conditions resulting in yield reduction [23-25]. The reason for the yield reduction through plastic mulching may be the soil temperature going beyond the optimum during the growing season.

There are still some shortcomings in this study. It is reported that the black plastic film does not allow sunlight to pass through onto the soil [15]. Thus, photosynthesis does not take place in soil in absence of sunlight below the black film. Hence, it arrests growth completely. The black plastic mulch is helpful in conserving moisture and controlling weed growth. However, it may increase the soil temperature.

5. Acknowledgements

This study was made possible through the help of Chen hao and Liu yan-fei (Northwest A&F University), I would like to thank them for helping statistical analyses and providing helpful comments.

NOTES