Reduction of Undercuts in Fillet Welded Joints Using Taguchi Optimization Method ()

1. Introduction

Weld bead geometry is severely negatively affected by the occurrence of the undercut phenomenon. Undercuts can be described as the presence of grooves along the edges of the weldment, usually observed in the welding of unskilled welders. These welders are often satisfied with their metal material joints simply being held together by the solidified molten weld metal upon cooling, without considering whether or not there was an adequate molten weld metal penetration in the parent metal’s joints gaps. Petershagen [1] described an undercut as an irregular groove along the toe of a weld. Undercuts can also be seen as unfilled grooves in the base metal at the edge of the weld. These undercuts could similarly be caused by inappropriate electrode angle, excessive current and unacceptable travel speed. Petershagen [1] also said that undercuts are inherent in the welding process and may occur in either the base or filler metal. He classified undercuts into three categories. Undercuts of category one are referred to as wide and curved. Undercuts of category two are narrow and undercuts of category three are considered micro-flaws, with depth less than 0.25 mm. Undercuts of category three are believed to be unavoidable during welding and impossible to detect by visual inspection. Xu et al. [2] also said that bead undercut defects not only affect the appearance of weld beads, but also cause a severe stress concentration at the weld edges, which has a great effect on the reliability of the weld joints. Whatever the category, insufficient penetration of molten weld metal which is a major cause of undercuts, lowers the strength of the weldments, and this has led to structural failures of engineering projects. Major structural failures could lead to significant safety hazards.

This study attempts to find the most economic solutions of applying models, tested in other areas, to weld technology. This is all in the bid to optimize gas metal arc welding process parameters required to reduce the formation of undercuts to the barest minimum. The integrity of the weldment could be improved by tweaking the welding process and removing practices which undermine the process. The top and undersides of a weldment are expected to meet specific standards. The top side which constitutes the bead is expected to have optimized bead geometry, where the bead height and width are preferred to be smaller in size. The undersides, where undercuts predominantly occur, usually appear in between parent metal joints at the point where the weldment ought to have leveled out with the parent metals.

When there is insufficient molten weld metal penetration and the point where the weld metal does not level out with the parent metal, the difference between the parent metal and the weld metal determines the size of the weld undercut. Garg et al. [3] were of the opinion that a weld undercut occurs when the weld reduces the cross- sectional thickness of the parent metal.

The heat affected zone (HAZ) includes the part of the parent metal which is intensively affected by the arc heat. Parts of this parent metal may melt and the melt would either flow into a lower part of the parent metal or vaporize into the atmosphere. This movement of melt could eventually cause the cross-sectional area of the parent metal to be reduced.

Alloying elements vaporization must also be taken into consideration. Alloying elements like zinc and magnesium are very volatile when exposed to intense heat. Therefore, if these alloying elements are exposed to prolonged heat application during welding, they have the tendency to vaporize. Garg et al. [3] asserted that undercuts could be caused by excessive current. Excessive current usually causes weld spatter; weld spatters are metal droplets expelled from the weld/weld pool that stick to the surrounding surfaces of the weldment.

The authors also said that insufficient deposition of filler metal during welding could also cause weld undercut. This insufficient filler metal deposition could be as a result of very low voltage and current. These very low levels of voltage and current may not generate enough arc heat to melt the filler metal. Xu et al. [2] has suggested that in gas metal arc welding process, by increasing the welding speed beyond a particular threshold value, the weld formation quality will worsen and bead undercut defects would occur. It has also been suggested that these undercuts can be filled or repaired by welding them with smaller electrodes.

In this study, “the smaller the better part” of the Taguchi method is applied to reduce the formation of weld undercuts to the barest minimum.

2. Materials and Methods

Five weld joints were made on a 60 mm × 40 mm × 10 mm mild steel plate. This process was repeated nine times producing a total of forty five weld joints. For each application of the nine process parameters, the five undercuts made in each weld joint were measured and the average recorded. In all, a total of nine undercuts were recorded as presented in Table 1. Figure 1 shows the undercut scan gauge used for measuring the depth of undercut.

Spadea and Frank [5] cited in their work that Petershagen [1] survey also indicated that undercuts are generally characterized by their length, height, and width. In addition, the transverse orthogonal plane angel, ρ, and the notch root radius, r, were used to describe the geometry of an undercut as shown in Figure 2.

![]()

Figure 1. Wiki Scan weld undercut measurement gauge [4] .

![]()

Table 1. Orthogonal matrix layout and undercut measurements of corresponding weldments.

The methods adopted in conducting this study are as follows:

An L9 Taguchi orthogonal matrix layout, shown in Table 1 was chosen for this study;

A welding operation was done by utilizing the range of process parameters as shown in Table 2 and using a gas metal arc welding (GMAW) machine to join a pair of 60 mm × 40 mm × 10 mm mild steel plate;

Undercuts in the weldments were measured and recorded;

The Taguchi optimization process relating to the smaller the better was applied using Equation (1);

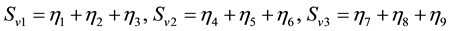

The signal to noise ratio generated was clustered and arranged into their respective positions indicating their optimum process parameters as shown in Table 3;

Signal to noise ratio vs process parameters graphs were drawn to show the effect of S/N ratios on the process parameters in relation to the optimum process parameters as shown in Figures 3-5;

![]()

Table 2. Range of process parameters.

![]()

Table 3. Sum and average S/N ratio for each process parameter.

*signifies the optimum level based on the smaller-the-better criterion.

The analysis of variance of the parameters shown in Table 4 are calculated for to determine the contribution of each process parameter to the formation of undercuts;

A confirmation test as shown in Table 5 is done using Equation (4). This is done to find out if the optimized process parameters have better mechanical properties or signal to noise ratio than those obtained from using the existing process parameters.

3. Results

3.1. Presentation of Results

Table 1 shows the orthogonal matrix layout and undercut measurement results.

Table 2 shows the range of process parameters.

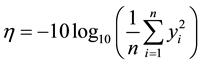

Applying the smaller the better methodology by using Equation (1).

Signal to Noise ratio for the smaller the better function is

(1)

(1)

where, n is the sample size and y is the mean weld undercut in mm.

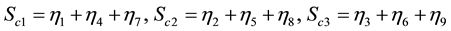

The S/N ratio for the individual control factors as extracted from Table 1, are as calculated hereunder:

For voltage

![]()

Table 4. Analysis of variance (ANOVA).

![]()

Table 5. Confirmation test results.

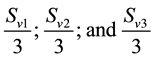

Average S/N ratio for voltage

For current,

Average S/N ratio for current

For welding speed,

Average S/N ratio for welding speed

![]()

The sum and average S/N ratios for the process parameters are shown in Table 3.

Athreya and Venkatesh [6] calculated the surface roughness of lathe facing operation by using the smaller the better type of Taguchi method and selected the factor levels corresponding to the highest S/N ratio as the optimum process parameters. From Table 3, the optimum level corresponding to the highest S/N Ratio is A2-B1-C3.

Figures 3-5 show the S/N ratio graph where the dashed line is the value of the total mean of the S/N ratios. The Figures clearly show the interactions between the levels of each process parameters.

Analysis of Variance (ANOVA)

Table 4 shows the analysis of variance tabulation.

Sum of square, ![]() [7] (1)

[7] (1)

where n is the number of test conducted

% Contribution = ![]() [7] (2)

[7] (2)

F-ratio = ![]() [7] (3)

[7] (3)

Confirmation Test

Using ![]() (4)

(4)

where ![]() is the total mean of S/N ratio;

is the total mean of S/N ratio; ![]() is the mean of S/N ratio at the optimal level and n is the number of main welding parameters.

is the mean of S/N ratio at the optimal level and n is the number of main welding parameters.

The optimal parameters are A2-B1-C3 and the corresponding S/N ratios are 22.6170, 23.8560 and 23.9907 respectively.

The total mean of S/N ratio, ![]()

Therefore, ![]()

The existing process parameters in use for welding processes are A3-B1-C2.

Its S/N ratio is calculated as follows:

![]()

Table 5 shows the confirmation test results.

3.2. Discussion of Results

This paper tends to use the Taguchi optimization tool relating to the smaller the better technique in reducing the depth of weld undercut made during the welding operations of weldments. The orthogonal matrix layout in Table 1 was used to allocate the process parameters in Table 2, these process parameters were used to make weldments. Nine welding operations were carried out in this experiment. Each welding operation was conducted five times and the corresponding undercuts were measured. The average of these five weldments obtained from one welding operation was recorded. The values of these measurements are recorded in Table 1. The signal to noise ratio relating to the smaller the better technique was obtained for the values of the undercuts in Table 1. The average value of the calculated s/n ratios were recorded in Table 3.

From Table 3, the optimum process parameters were obtained utilizing the smaller the better technique of the Taguchi method. The obtained process parameters are A2-B1-C3. This indicates that a welding process parameter consisting of 20 V, a current of 180 A and a welding speed of 130 min/s are required to make an undercut in the weldment to a value of 0.03 mm. The existing process parameter utilized by the company is A1-B3-C1 which made an undercut with an average depth of 0.09 mm. By using the optimum welding process parameters, an improvement of an S/N ratio of 2.336 and 0.06 mm depth of undercut were made over the S/N ratio and depth of cut made by applying the existing process parameters.

The effects of the S/N ratios on the process parameters were also investigated and are expressed in Figures 3-5. Figure 3, shows the effect of S/N ratio on voltage, the dashed line is the value of the total mean of the S/N ratios and it is indicated by dote lines. From Figure 3, it is seen that a voltage of 20V that has an S/N ratio of 22.6170 db is above the total mean S/N ratio of 22.3259 db. Whereas, a voltage of 18V which has an S/N ratio of 22.1251 db and another voltage of 22 V with an S/N ratio of 22.2357 db, are both below the total mean S/N ratio. This indicates that using the voltage of 20V has the probability of reducing the noise level of the welding operation that can result in the production of weldment with the lowest undercut. Figure 4, shows the effect of the S/N ratio on the welding current. From Figure 4, it is seen that a current of 180 A with an S/N ratio of 23.8560 db was above the total mean S/N ratio, whereas, the 200 A current, having an S/N ratio of 21.8656 and a current of 260 A with an S/N ratio of 21.2562 db fall below the total mean value. The total mean value is a threshold value that determines the viability of the process parameter. This further shows that from the interactions of these components of the process parameters (in this case current), the 180 A current with an S/N ratio of 23.8560 db has the ability of reducing the noise, in this case, noise are likely factors that would adversely affect the welding operation capacity to a very insignificant value that can eventually produce a weldment with the lowest undercut.

Figure 5 shows the effect of the S/N ratio on the welding speed. From Figure 5, it is observed that a welding speed of 85 mm/s having an S/N ratio of 20.9511 and another welding speed of 105 mm/s with an S/N ratio of 22.0360 db respectively were below the total mean S/N ratio. However, the welding speed of 130 mm/s having an S/N ratio of 23.9907 db is above the total mean S/N ratio This indicates that the third component of the welding speed parameter, which is 130 mm/s having an S/N ratio of 23.9907 is the optimum component of welding speed and this component has the ability to reduce noise to the barest minimum.

However, the extent of these process parameters consisting of voltage, current and welding speed in reducing the depth of the weld undercut were measured by determining the contribution made by each process parameter. The contribution made by these process parameters were determined by applying the analysis of variance approach as presented in Table 4.

From Table 4, it is observed that the welding speed has the greatest contribution of 3.24%, followed by current, which contributed 2.53% and voltage has the lowest contribution of 0.09%. This indicates that as the welding speed increase, which also reduces the welding time and with a significant amount of current, a weldment with insignificant or no undercut is likely to be produced. From this study, voltage does not significantly affect the formation of undercuts.

Table 5 shows the confirmation test results. The importance of the confirmation test is to determine the effectiveness and reliability status of the optimum process parameters over the existing process parameters used by the welding and fabrication operators. From Table 5, it is observed that the existing process parameters of A1- B3-C1, utilized by the company has an S/N ratio of 23.4759 db which produced a weldment with an average undercut measurement of 0.09 mm. The optimum process parameters of A2-B1-C3 obtained by applying the Taguchi method has an S/N ratio of 25.8119 db which produced a weldment with an average undercut of 0.03mm, from the above, it can be deduced that by using the optimum process parameters there is a reduction of 0.06mm of undercut from 0.09 mm obtained in the weldment made by using the existing process parameters. This also gave an improvement in S/N ratio of 2.3360 db over that made by using the existing process parameters.

4. Conclusions

Weld undercuts are a very important factor considered in assessing the integrity of weldments. The higher the depth of the undercut, the lower the integrity of the weldment. Therefore, this study is designed to determine optimum process parameters that can reduce this undercut to the barest minimum. The application of the wrong process parameters can greatly affect the integrity of the weldment.

Taguchi orthogonal array, L9, was used to design the various compositions or combinations of the process parameters. These process parameters were used to make weldments. The undercuts formed in these weldments were measured by using a Wiki Scan as a laser based tool, which does a 3D scan of joints and weld information on size, porosity and undercut.

The S/N ratios of the measured undercuts were determined and the optimum process parameters were obtained by applying “the smaller the better technique” of the Taguchi method. Also the contributions of each of the process parameters were determined to find out the extent to which each of the process parameters affected the formation of undercut in the corresponding weldment. It was found that welding speed has the greatest input in the reduction of weld undercuts.

NOTES

*Corresponding author.