A Monte Carlo Based Robustness Optimization Method in New Product Design Process: A Case Study ()

1. Monte Carlo Method

Monte Carlo method is a computer-based simulation or experiment method. It approximately simulates and solves mathematical or physical stochastic problem with statistical random sampling. Compared with traditional algebraic method, due to their reliance on repeated computation of random or pseudo-random numbers, Monte Carlo method can apply Normal distribution, Exponential distribution, Weibull distribution etc. to model phenomena with significant uncertainty in inputs when it is unfeasible or impossible to compute an exact result with a deterministic algorithm, and does not need to know parameter’s distribution type and probability parameter [1] -[5] . In new product design, usually design parameter is a random variable that follows a probability distribution. Design parameter is a key impact factor to design robustness, and distribution of these design parameters determines greatly robustness of output response. It is not reliable to optimize this product design problem using traditional deterministic method. How to find the optimum value of these design parameters is an important problem to improve the design robustness of new product. Here, we propose a robustness optimization method of new product based on Monte Carlo simulation.

Procedures are as followed [6] -[10] :

1) To analyze the problem existing in new product design, and define the relationship between design variables  and response output as a response surface model

and response output as a response surface model ;

;

2) To analyze design variables’ distribution types and define design variables’ distribution characteristics, such as mean and standard deviation, etc.;

3) To sample from populations of random design variables X, and get the sample ;

;

4) To bring sample  into position error model between response surface model and standard value,

into position error model between response surface model and standard value,  , then get a r position error sample and compose an experiment

, then get a r position error sample and compose an experiment

, (

, ( is response output,

is response output, );

);

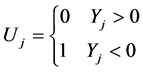

5) To check if it meets ,

,  is allowed error maximum.

is allowed error maximum.

6) To repeat step 2) to 5) by k times, and calculate the number of  in all independent samples

in all independent samples ,

,

, here

, here  is the number of

is the number of ,

, ;

;

7) To calculate reliability ratio . If

. If  (

( is acceptable reliability), then process or product is robust, otherwise we need to modify the precision value of random design variables to enhance reliability ratio and robustness of the manufacture process, then the manufacture process is optimized.

is acceptable reliability), then process or product is robust, otherwise we need to modify the precision value of random design variables to enhance reliability ratio and robustness of the manufacture process, then the manufacture process is optimized.

2. Case Study

Considering design of a pressure container, according to mechanics of materials, the pressure container’s axial stress is , hoop stress is

, hoop stress is , here

, here  is internal pressure of container;

is internal pressure of container;  is wall thickness of container;

is wall thickness of container;  is internal radius of container;

is internal radius of container;  is half height of container. Material of container is 15 MnV. Through observation of experiment, we defined the design variables and their distribution characteristics as followed: internal work pressure of container

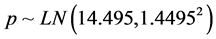

is half height of container. Material of container is 15 MnV. Through observation of experiment, we defined the design variables and their distribution characteristics as followed: internal work pressure of container  follows lognormal distribution

follows lognormal distribution the tolerance of

the tolerance of  is (10, 20), the material strength limit

is (10, 20), the material strength limit  follows lognormal distribution

follows lognormal distribution the tolerance of

the tolerance of  is (340, 420), wall thickness of container

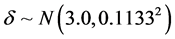

is (340, 420), wall thickness of container  follows normal distribution

follows normal distribution the tolerance of

the tolerance of  is (1.5, 4.5), internal radius of container R follows normal distribution

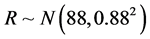

is (1.5, 4.5), internal radius of container R follows normal distribution the tolerance of R is (50, 100), half height of container H follows normal distribution

the tolerance of R is (50, 100), half height of container H follows normal distribution , the tolerance of H is (130, 210). Our objective is to maximize container’s volume under 95% failure probability (confidence level) of strength and container size falling Interval

, the tolerance of H is (130, 210). Our objective is to maximize container’s volume under 95% failure probability (confidence level) of strength and container size falling Interval .

.

As known, our objective function is volume maximum of the pressure container, that is

Constraints are

Firstly we established response surface model of response variables  concerned pressure container and constraints condition, and run Monte Carlo experiment 3000 times using Crystal Ball 7. According to Anderson-Darling testing, Chi-Square testing and K-S testing [11] -[13] , we can fit the probability distribution type of all four response variables as Normal distribution, Gamma distribution, Gamma distribution and Beta distribution, see Table1

concerned pressure container and constraints condition, and run Monte Carlo experiment 3000 times using Crystal Ball 7. According to Anderson-Darling testing, Chi-Square testing and K-S testing [11] -[13] , we can fit the probability distribution type of all four response variables as Normal distribution, Gamma distribution, Gamma distribution and Beta distribution, see Table1

Then we get probability distribution and cumulative probability distribution of response variable and constraints as showed in Figure 1.

1) Robust analysis

We can know from Figure 2 that probability which product design met constraint g1 is , and probability which product design met constraint g2 is

, and probability which product design met constraint g2 is , and probability which product design met constraint g3 is

, and probability which product design met constraint g3 is  under current design variables value. That iswave range of constraints both g1 and g2 go beyond their allowed range. According to requirements, current response output value is not robust and need to improve product design level.

under current design variables value. That iswave range of constraints both g1 and g2 go beyond their allowed range. According to requirements, current response output value is not robust and need to improve product design level.

2) Sensitivity analysis

We can know from Sensitivity Analysis of Response Variables and Constraints in Figure 3 that the significant impact factors of volume function f of pressure container are  (positive correlation) and

(positive correlation) and  (positive correlation) in order; the significant impact factors of constraint

(positive correlation) in order; the significant impact factors of constraint  are

are  (positive correlation),

(positive correlation),  (negative correlation) and

(negative correlation) and  (negative correlation) in order; the significant impact factors of constraint

(negative correlation) in order; the significant impact factors of constraint  are

are  (positive correlation),

(positive correlation),  (negative correlation) and

(negative correlation) and  (negative correlation) in order; the significant impact factors of constraint

(negative correlation) in order; the significant impact factors of constraint  are

are  (positive correlation) and

(positive correlation) and  (negative correlation) in order.

(negative correlation) in order.

3) Modification of design variables precision

According to relationships between design variables and response output variable, and contributions to variance view from Figure 3, we modified parameter values of the design variables  to

to  ,

,  ,

,  ,

,  ,

,  , and get the corresponding probability distribution and cumulative probability distribution as followed in Figure 4.

, and get the corresponding probability distribution and cumulative probability distribution as followed in Figure 4.

After Modification of design variables precision, we analyze robustness of response variable and constraints

Table 1 . Analysis of response variables’ distribution characteristics.

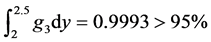

again, and get the probability that product design met constraints g1 is , and the probability that product design met constraints g2 is

, and the probability that product design met constraints g2 is , and the probability that product design met constraints g3 is

, and the probability that product design met constraints g3 is , which reached product design requirements, that is, pressure container is robust enough, and pass percentage of pressure container has been enhanced greatly. And the maximum volume of container is

, which reached product design requirements, that is, pressure container is robust enough, and pass percentage of pressure container has been enhanced greatly. And the maximum volume of container is , product robustness has been greatly improved. Meanwhile, we knew from sensitivity analysis of response variables in Figure 3 that we should keep monitoring the fluctuation of the significant impact factors of response variables and constraints to hold robustness of pressure container.

, product robustness has been greatly improved. Meanwhile, we knew from sensitivity analysis of response variables in Figure 3 that we should keep monitoring the fluctuation of the significant impact factors of response variables and constraints to hold robustness of pressure container.

4) Design optimization

Now we further optimize the pressure container to enhance the design robustness using OptQuest optimizer. Here we create the OptQuest model and run simulation experiments 1500 times according to distribution characteristics of design variables and constraints condition [4] -[6] , and get the optimum of design variables  are

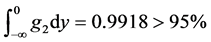

are  in Table 2, then the probability that product design met constraints g1 are

in Table 2, then the probability that product design met constraints g1 are , and the probability that product design met constraints g2 was

, and the probability that product design met constraints g2 was , and the probability that product design met constraints g3 is

, and the probability that product design met constraints g3 is  from Figure 5, and the maximum volume of container is

from Figure 5, and the maximum volume of container is  as Figure 6

as Figure 6

showed, so design robustness of pressure container has been further improved than that of last time.

Table 2. Optimum design settings of pressure container with OptQuest.

Figure 6. Optimum design performance gragh of pressure container with OptQuest.

3. Conclusion

When random changes exist in design variables, traditional determined optimization method cannot guarantee robustness of product and process design to the extent. While Monte Carlo method can be used to precision control and optimization in product and process design, which can avoid increasing cost due to duplicate experiments and excessive design precision, as well as low pass percentage due to deficient design precision. In robust analysis and design, Monte Carlo method also can study on change of response model of product and process brought by modification of design variables, get probability distribution and statistical parameters’ values of response variables, further improve design robustness of product and process and realize robustness design and optimization of product and process. It proved that analysis and optimization of response surface model based on Monte Carlo method was a good robustness design method, and can markedly improve robustness, precision and pass percentage of product and process.

Funding

It was supported by National Natural Science Foundation of China (71102047, 71302016, 71302017) and “The Fundamental Research Funds for the Central Universities” (NKZXB1202). Many thanks are also given to anonymous reviewers.