Development of Alkylation Toluene with Methanol for Fuel on Modified ZSM-5 Zeolites by Amphoteric Surfactant ()

![]()

Received November 11

th, 2013; revised December 18

th, 2013; accepted January 10

th, 2014

Figure 1. Effect of temperature on the product composition on 10% Sr/ZSM-5.

![]()

Figure 2. Effect of temperature on the product composition on 5% Sr/ZSM-5.

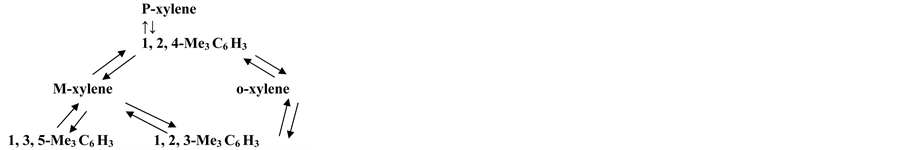

At high methanol concentration, it is possible that iso- merization of o- and p-xylene formed in the first step proceeds with a bimolecular mechanism according to the following scheme of parallel reactions.

In this way formation of 1, 2, 4- & 1, 2, 3- trimethyl- benzene (TMB) is rationalized. In turn, m-xylene is formed by dealkylation of TMB up to equilibrium con-

![]()

Figure 3. Effect of temperature on % composition on 2.5% Sr/ZSM-5.

![]()

Figure 4. Effect of temperature on % total conversion of alkylation of toluene on different catalysts.

ditions.

On the two catalysts 2.5% Sr/ZSM-5 and 5% Sr/ ZSM-5, (Figures 2, 3), show that the temperature influ- ence beyond 400˚C gives a considerable increase in m-xylene to 24%, 14% respectively at a reaction temper- ature of 500˚C. But on 10% Sr/ZSM-5 catalyst, a linear increase in m-xylene production is observed to reach a value of 13% at 500˚C.

Also, when comparing the Figures 2-4, it appears that using 2.5% Sr/ZSM-5 catalyst o-xylene increases with the increase in temperature to reach a value of 6% at 400˚C then has a constant value with futher increase in temperature. Nevertheless the catalyst 5% Sr/ZSM-5 has a maximum value of 4% at 450˚C, while 10% SR/ZSM-5 catalyst has a maximum value of 7.5% at 450˚C.

This can be demonstrated to that the diffusion in the micropores may not be the only reason for the high para selectivity of shape selective catalysts.

It is reasoned that ions such as 10% Sr in the pores of the ZSM-5 decrease the free diameter of the catalyst and favor diffusion of sterically less requiring para isomer.

Also chemisorption of various isomers and/or toluene can play a significant role in the performance of the cat- alyst [11]. This takes in to account that the o-xylene is more strongly adsorbed than the Meta isomer, so differ- ent selectivity values would have been expected (Meta > ortho), Figures 2-4.

Tables 1, 2 show the conversion of toluene and the selectivity of the three catalysts understudy for producing xylenes. Also these Figures 5, 6 show that the selectivity of 5% Sr/ZSM-5 and 2.5% Sr/ZSM-5 catalysts for para xylene production are considerably the same till a con- version of a value 45% at which the catalyst 5% Sr/ ZSM-5 reaches its maximum, but the selectivity increases with further increase in conversion on the catalyst 2.5% Sr/ZSM-5.

This confirms that the reaction proceeds up to the iso- merization equilibrium (step 2) of the previous equation of the alkylation reaction of toluene, and is accompanied by a rapid release of paraxylene (due to its minor adsorp- tion) with consequently a shift in equilibrium towards formation of this isomer and enhance para selectivity. The catalyst 2.5% Sr/ZSM-5 has the highest selectivity towards m-xylene at all temperatures under study.

The selectivity plot for o-xylene production (Table 1) is lower than the corresponding for metaxylene values. The maximum value for production of metaxylene was obtained at 500˚C on the catalyst 2.5% Sr/ZSM-5.

The results presented in Table 1 revealed that the se- lectivity for the production of the three xylene isomers may be due to the close relation between the acidity of the exchanged zeolites and the selective adsorption of the xylene isomers. The para isomer is adsorbed less than the other for more acidic zeolite ZSM-5.

![]()

![]()

Table 1. Reaction products for alkylation of toluene at different temperatures.

![]()

Table 2. Reaction products for alkylation of toluene at different temperatures and catalysts.

The applications of (AB) as emulsifier are based on its capacity for adsorption at various interfaces with conse- quent alteration of the properties of surface. The most fundamental effect of adsorption of (AB) is the reduction of interfacial tension which, in the case of equilibrium- reversible adsorption, is described by the Gibbs equation.

A series of experiments was conducted at 25C em- ploying a mixing time of 15 min. And a stirring rate of 1200 rpm. The results obtained are depicted in Figure 5 in terms of the emulsion stability, interfacial tension be- tween toluene/methanol versus the molar concentration of AB employed. Emulsion stability was improved as the concentration of AB increased with a maximum being attained at 5 mol/l. At the same time, the interfacial ten- sion between toluene/methanol phase decreased from 31 mN/m to 18 mN/m. Such results demonstrate that an increase in the AB concentration was accompanied by its increase in emulsion stability.

The explanation for these results is that those mole- cules of AB that are highly effective at reducing the crit- ical micelle concentration and interfacial tension between toluene/water, toluene is solubilized in the micelle core. The additive AB have more than one group capable of forming hydrogen bond, with methanol in a terminal po- lar grouping appear to produce greater dispersion and emulsion stability.

It can be suggested that the adsorption layer of surfac- tant with its hydrophilic end oriented towards aqueous layer agree with author publication early [12]. This emul- sion toluene/methanol stablized by the additive AB. The sign of the charge on the dispersed droplets is amphi-

pathic ion. The presence of the additive in interfacial film between toluene/methanol close approach two phases droplets to each other which can be enhance degree of alkylation.

At the optimum conditions 10% Sr/ZSM-5, LHSV equals 4, toluene/methanol ratio of 1:3 and temperature

450 C. The alkylation of toluene with methanol was car- ried out. Enhancing of the concentration of the product was achieved. Detailed analysis of the products is given in Table 3.

It is clear that the yield of alkylation increase and se- lectivity towards p-xylene and o-xylene also incease. These results can be explained according to micelle for- mation and interfacial tension. Reaction occurring at the methanol/toluene interface strongly facilitating reaction by micelles catalyzed reaction and does not depend on its concentration.

![]()

![]()

![]()

Table 3. Reaction products for alkylation of toluene at different temperatures.

![]()

Figure 5. Effect of concentration of the additive on interfacial tension of toluene/methanol and emulsion stability.

![]()

Figure 6. Effect of temperature on the product composition on the modified 10% Sr/ZSM-5.

4. Conclusion

The yield of alkylation of toluene and its selectivity to- wards p-xylene and o-xylene increase by N-octyl-N- benzyl-N-methylglyene. These results are discussed

according to micelle formation and interfacial tension. Reaction occurring at the methanol/toluene interface strongly facilitating reaction by micelles catalyzed reac- tion does not depend on its concentration

REFERENCES

[1] Th. F. Tadros, “In Surfactant in Solution,” Plenun Press, New York, 1984, pp. 1501-1532

[2] D. O. Shah, “Macro- and Micro-Emulsion, Theory and Applications,” American Chemical Society, Washington DC, 1985.

[3] J. Drelich, A. Atia, M. Yalamanchil and J. D. Miller, “Formation and Wetting Characteristics of Adsorbed Layers of Unsaturated Carboxylic Acids at a Fluorite Surface,” Journal of Colloid and Interface Science, Vol. 178, No. 2, 1996, pp. 720-732. http://dx.doi.org/10.1006/jcis.1996.0170

[4] J. A. Mielczarskin and C. Mielczarski, “Determination of Molecular Orientation and Thickness of Self-Assembled Monolayers of Oleate on Apatite by FTIR Reflection Spectroscopy,” The Journal of Physical Chemistry, Vol. 99, No. 10, 1995, pp. 3206-3217. http://dx.doi.org/10.1021/j100010a035

[5] P. Somasundaran, “Separation and Purification Methods,” Vol. 1, Marcel Dekker, New York, 1972, p.117.

[6] P. M. Holland and D. N. Rubingh, “Mixed Surfactant System,” American Chemical Society, Washington DC, 1992. http://dx.doi.org/10.1021/bk-1992-0501

[7] J. L. Sotelo, M. A. Vguina, J. L. Valverde and D. P. Serano, “Kinetics of Toluene Alkylation with Methanol over Magnesium-Modified ZSM-5,” Industrial & Engineering Chemistry Research, Vol. 32, No. 11, 1993, 2548-2554. http://dx.doi.org/10.1021/ie00023a018

[8] M. Guisnet and P. Magnoux, “Coking and Deactivation of Zeolites: Influence of the Pore Structure,” Applied Catalysis, Vol. 54, No. 1, 1989, pp. 1-27. http://dx.doi.org/10.1016/S0166-9834(00)82350-7

[9] D. M. Bibby, R. F. Dowe and G. M. Mcleellan, “Coke Formation in High-Silica Zeolites,” Applied Catalysis A: General, Vol. 93, No. 1, 1992, pp. 1-34. http://dx.doi.org/10.1016/0926-860X(92)80291-J

[10] A. M. A. Omar, “Separation of Emulsifiable Oil from a Flotation Solution by Surface Tension Control,” Adsorption science & Technology, Vol. 19, No. 1, 2001, pp. 91- 100. http://dx.doi.org/10.1260/0263617011494006.

[11] S. G. T. Bhat, “Selectivity for Xylene Isomers in the Reaction of Alkylation of Toluene with Methanol on Zeolite Catalysts,” Journal of Catalysis, Vol. 75, No. 1, 1982, pp. 196-199. http://dx.doi.org/10.1016/0021-9517(82)90136-1

[12] S. M. Csicsery, “Acid Catalyzed Isomerization of Dialkylbenzenes,” The Journal of Organic Chemistry, Vol. 34, No. 11, 1969, pp. 3338-3342. http://dx.doi.org/10.1021/jo01263a026