1. Introduction

Starch is widely used in different industries [1]. Textile industry, for example, uses large quantities of starch in warp yarn sizing [2], printing and finishing [3]. In common practice, however, modified starches are usually employed since the properties of native starch cannot cope with those required for such purposes as well as for other particular end-use [4,5].

Starch undergoes chemical modification when it is subjected to oxidation [6], hydrolysis, esterification [7], etherification), grafting [8], and cross-linking [9]. Combined hydrolysis (or oxidation) and grafting [6] are also used to effect starch modification.

The reaction involved in the chemical modification of starch causes significant changes in its physical as well as in its chemical structure. As a result, the solubility, viscosity performance, film-forming properties, resistance to ageing, etc. can be adjusted as per the end use required. Indeed, newly synthesized polymeric materials based on starch present a very fascinating field of research with unlimited future possibilities for promotion of starch utilization. Furthermore, starch is one of the most effective bioresource for technologies such as nanotechnology [7].

With the above in mind, current work presents an innovative route for synthesis of novel starch hybrid, namely, polycarboxylic starches. The innovation is based on carboxymethylation of poly (MAA)-starch graft copolymer as well as poly (MAA)-Starch composite vis-avis native starch. These starch hybrids are monitored for carboxyl content and rheological properties.

2. Experimental

2.1. Materials

Maize starch was supplied by the Egyptian Starch and Glucose manufacturing Company, Cairo, Egypt. Methacrylic acid (MAA), sodium hydroxide, monochloroacetic acid, potassium persulphate, sodium thiosulphate, hydrochloric acid, sodium carbonate, ethanol, and acetone were of laboratory grade chemicals.

2.2. Grafting Method

Unless otherwise indicated, the grafted starch was prepared by mixing 10 g starch with 100 ml water in a flask. The latter was placed in a thermostatic water bath adjusted at 65˚C, and the starch/water mixture therein was subjected to continuous mechanical stirring (200 rpm) to get homogenized slurry. MAA monomer {75% based on weight of starch, (ows)} was then added to the homogenized slurry while stirring. After that, the components of redox initiator system were added simultaneously. This system consisted of a sodium thiosulphate at concentration of 1.1 mmol/l and potassium persulphate 3.3 mmol/l. Polymerization system was allowed to proceed for 60 minutes at 65˚C with continuous stirring. The material to liquor ratio was 1:10. After 60 minutes—reaction, polymerization was ceased by adding 10 ml of 0.1% hydroquinone solution. At this end, the polymerization products in the flask were neutralized using 1% sodium carbonate solution then poured over ethanol, where a precipitate was formed. The so obtained precipitate is referred to as “composite”. The latter consists of Poly (MAA)-starch graft copolymer, poly (MAA) (homopolymer), oxidized starch, and unreacted starch. The composite was soxhlet extracted using methanol to remove the homopolymer. The residual precipitate represents the poly (MAA)-starch graft copolymer.

2.3. Carboxymethylation Method

Unless otherwise stated carboxy-methylation of starch, Poly (MAA)-starch composite and Poly (MAA)-starch graft copolymer was carried out as follow: sodium hydroxide solution (20% ows), was added gradually to 100 g starch in a flask with continuous mechanical stirring (200 rpm). This was followed by addition of monochloroacetic acid solution (95% ows) after being neutralized with sodium carbonate while stirring. Stirring was continued till the flask contents were completely homogenized. The flask was then transferred to a thermostatic water bath and reaction was allowed to proceed under continuous mechanical stirring at 70˚C for 120 minutes. At this end, the reaction product was precipitated and washed several times in ethanol then dried at 50˚C in an oven [10].

2.4. Cooking Process

An aqueous dispersion of starch or the modified starches under investigation was prepared at a concentration of 10% solid content. The dispersion was then homogenized before heating by use of a mechanical stirrer (250 rpm)

for 10 minutes. Cooking was effected by heating the sample under continuous stirring in a thermostatic water bath where the temperature was raised from 25˚C to 95˚C in a rate of 2.5˚C per minute then kept constant at 95˚C for 30 minutes cooking to bring about a paste. Temperature of this paste was lowered to 25˚C; meanwhile stirring was reduced to the minimum degree within 15 minutes.

2.5. Analysis

The carboxyl content of starch and the modified starches viz. the copolymer and the composite before and after etherification via carboxymethylation was determined according to a reported method [11], which is based on acid-base titration.

The rheological properties were measured using Roto-Visco RV 20 under the following experimental conditions. Rate of shear was between 129 - 1290 S−1 and temperature 80˚C. The apparent viscosity was calculated using the following formula

η: St/D

where:

η: apparent viscosity (mPa.S), D: rate of shear (S−1), St: shear stress (mPa).

3. Results and Discussion

3.1. Tentative Mechanisms

Etherification of starch via reaction with monochloroacetic acid in presence of sodium hydroxide has been extensively studied [7]. The essential product of this reaction is the well-known carboxymethyl starch, CMS, which is commercially available in different types. Reaction involved in carboxymrthylation of starch was reported. Polymerization of starch with acrylic monomers has also been a subject of many investigations [12]. The polymerization process comprises a system consisting of starch, MAA monomer, K2S2O8/Na2S2O3 redox initiator and water. The system is very complex since it entails several reactions which may be outlined as follows: a) The redox initiator decomposes to yield primary free radial species, namely, sulphate ion radical hydroxyl radicals, and, thiosulphate ion free radicals. b) These free radicals attack the starch hydroxyl where a hydrogen atom is abstracted thereby producing starch macroradical capable of initiating grafting of MAA. c) The primary free radicals can add to double bond of MAA and in so doing, the monomer molecule is converted to an excited state which can initiate the growth of a polymer via subsequent addition of monomer molecule. d) The primary free radicals attack the starch to give starch macroradicals which add oxygen and lend itself to an oxidative degradation process.

Obviously, then, the essential products of polymerization of MAA with starch are: poly (MAA)-starch graft copolymer formed according to d). In addition to these products intact starch is expected to be among the ultimate end products of the polymerization process. Thus when polymerization products are considered we are indeed dealing with a composite consisting of all these products taken together. The word starch hybrids is used in this work to refer to the composite and/or the copolymer after being subjected to carboxymethylation.

Needless to say those, the carboxy-methylation of starch as well as its polymerization with acrylic acid and other vinyl monomers have gained much attention. On the contrary, no work so far has been published on the behavior of starch graft copolymer or starch composite towards carboxymethylation under different conditions. The present work is undertaken as an endeavor to fulfill this gap. Products of polymerization of starch with MAA before and after carboxy-methylation were analyzed for carboxyl content and rheological products and the results obtained are presented and discussed as given under.

3.2. Carboxyl Content

3.2.1. Dependence of the Carboxyl Groups of Starch Due to Carboxymethylation on the Magnitude of Poly (MAA) Content

Table 1 shows the dependence of carboxymethylation on the MAA concentration used in synthesis of the copolymer of starch and starch composite. The monomer concentration is taken as a measure for the magnitude of poly (MAA) content in both copolymer and composite. This magnitude as well as the extent of carboxymethylation is expressed as m.eq.COOH/100g starch.

It is seen (Table 1) that using MAA concentration of 50%, 75%, and 100%, ows, brings about composite having 140, 172, and 190 meq.COOH/100g starch. This is rather expected since the poly (MAA) in the composite is directly related to the monomer concentration within this range (50% - 100% ows). Similar observation is encoun-

Table 1. Effect of MAA concentration on the carboxyl content of native starch, composite, and graft copolymer before and after carboxymethylation.

tered with the copolymer but with lower carboxyl contents as a result of homopoly (MAA) removal from the composite. Subjecting the composite and copolymer to carboxymethylation causes an enhancement in their carboxyl contents. However, it is certain a) that the carboxyl content due to carboxymethylation is much higher with the copolymer than the composite, b) that the higher the graft yield of the copolymer or the composite the lower the carboxyl content due to carboxymethylation and c) that the carboxyl content of starch due to carboxymethylation is significantly higher than the corresponding values of the copolymer and the composite. These findings lead to three main conclusions. First the composite is less susceptible to carboxymethylation than the copolymer by virtue of the presence of homopoly (MAA) which is inert to carboxymethylation. Second the magnitude of poly (MAA) in the form of graft or homopolymer adversely affect the carboxymethylation reaction by blocking some of starch hydroxyls and/or lowering the accessibility of starch through the ultimate association and physical entanglement of the poly (MAA) with the starch molecules. The third conclusion refers to the greater amenability of native starch to carboxymethylation as compared with the copolymer and the composite; a point which indeed is in full conformation with the first and second conclusions.

3.2.2. Concentration of Sodium Hydroxide

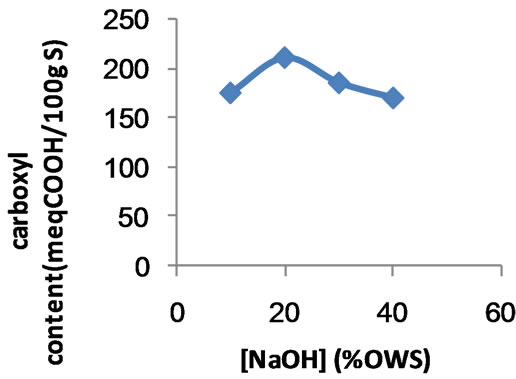

Figures 1-4 show different factors affecting the extent of carboxymethylation, expressed as carboxyl contents. One of these factors the concentration of sodium hydroxide. For this reason the carboxymethylation of the poly (MAA)- starch graft copolymer having 160 meq.COOH/100g sample was carried out using sodium hydroxide concentration within a range of 0% - 40% ows. The results obtained are shown in Figure 1.

Results of Figure 1 signify that carboxyl content of the copolymer due to carboxymethylation increases significantly by increasing the concentration of sodium hydroxide up to 20% ows. Above 20% the carboxyl content decreases sharply. That is, 20% sodium hydroxide concentration constitutes the optimum alkaline catalyst concentration for carboxymethylation since below or above this particular concentration lower extent of etherification is observed.

It seems likely that at 20% sodium hydroxide concentration, swelling of the copolymer with subsequent ease of diffusion of monochloroacetic acid are in full swing thereby enhancing the extent of carboxymethylation. Higher sodium hydroxide concentrations seems to function more in favour of gluconate formation and other side reactions which occur at the expense of carboxymethylation. Also likely to occur are de-etherification and degrafting, i.e., splitting off of the carboxymethyl group

Figure 1. Effect of sodium hydroxide concentration on the extent of carboxymethylation.

Figure 2. Effect of monochloroacetic acid concentration on the extent of carboxymethylation.

Figure 3. Effect of reaction temperature on the extent of carboxymethylation.

Figure 4. Effect of duration of carboxymethylation on the extent of carboxymethylation.

and the graft under the influence of sodium hydroxide concentration higher than 20%, ows.

3.2.3. Concentration of Monochloro-Acetic Acid

Another factor which governs the extent of carboxymethylation is monochloroacetic acid concentration. In accordance with previous reports dealing with starch [11], the extent of carboxymethylation of poly (MAA)-starch graft copolymer increases by increasing monochloroacetic acid concentration up to 95% ows, above which there is only a marginal increase This is clearly shown in Figure 2.

The significant enhancement in carboxymethylation by increasing monochloroacetic acid up to 95% ows, could be associated with greater availability of chloroacetic acid molecules in the vicinity of starch. It is understandable that the hydroxyls of starch are immobile and their reaction with monochloroacetic acid (C1CH2COOH) and sodium hydroxide molecules would essentially depend upon availability of C1CH2COOH and NaOH molecules in the proximity of the hydroxyl groups of starch molecules. On the other hand, the marginal increment of carboxymethylation could be interpreted in terms of reduction of the amount of hydroxyl group available on the starch molecules.

It seems that there is a certain amount of accessible hydroxyl group in the molecular structure of starch. Once these groups are blocked via graft polymerization and carboxymethylation, and/or accessible domains are removed under induced solubility, further reaction becomes difficult under the applied conditions. That is besides blocking starch hydroxyls during the carboxymethylation reaction, starch undergoes some changes which diminishes the susceptibility of starchtowards further etherification.

3.2.4. Temperature of Carboxymethylation

Figure 3 shows the effect of temperature on carboxymethylation of poly (MAA)-starch graft copolymer. As is evident the extent of carboxymethylation, expressed as carboxyl content, increases by raising the temperature within the range 30˚C - 70˚C. This could be associated with the favourable effect of temperature on a) swelling of the copolymer, b) diffusion of etherifying agents in the interior of the copolymer, c) formation of sodium starchate (St-O-Na), d) neutralization of monochloroacetic to from ClCH2COONa which is more reactive than the acid form, ClCH2COOH, and e) temperature which provides an additional energy source for faster mobility and collision of reactants and, therefore, greater carboxymethylation.