Microstructure and Strength Properties of Submicro and Nanocrystalline Nickel under Friction ()

1. Introduction

Modern technologies of intensive plastic deformation make it possible to obtain materials of submicroscopic and nanocrystalline structures with high strength properties. Formation of those structures under friction loading is possible due to localized processes of plastic deformation in surface volumes and accumulation of elastic energy will happen under conditions of rapid deformation.

Specific character of friction loading and temperature gradients facilitate kinetics of surface layers structural transformation. Under contact of surfaces and due to different height and diversity of geometrical shapes of rough edges (extrusions and intrusions), alternate stress functions in surface layer, which along with shear force actions leads to complicated stressed state of crystal lattice. Alternating loading of frictionally interacting extrusions and intrusions transforms into pulsating deformation of surface volumes causing fatigue behaviour. Temperature fluctuations of friction contact have considerable influence and together with initiation of return processes and dynamic recrystallization may result in thermal cycling, viscosity and creepage of surface layer material. These conditions determine formation of peculiar microstructure. Development of microstructure under friction interaction of surfaces of contacting objects should be regarded and discussed in accordance with oscillating character of its kinetics [1-3].

Results of electron-microscopic researches of surface layer microstructure under sliding friction, in accordance with study of dislocation structure by means of ferromagnetic resonance (FMR), are given in this paper [2]. Analysis of microstructure transformations of surface layer of metals (by the example of nickel) has been carried out on the ground of data complex. This analysis and certain number of results obtained earlier made it possible to draw a conclusion about reconstruction of surface layer microstructure at definite stages of loading into quasiuniform distribution of nonequilibrium dislocation aggregates and formation of highly dispersed substructures and nanostructures, which result in synergetic phenomenon [1-4].

2. Experimental Details

Transformation of dislocation structure in the near-surface layer of nickel under friction loading has been studied by means of electron microscopy and ferromagnetic resonance. Polycrystalline nickel with purity of 99.9% has been examined. Samples in the form of thin disks (5 × 0.1 mm2) were electrolytically polished and annealed in vacuum (0.133 MPa under 973 K). Friction test was carried out by means of a machine of type АЕ-5 with precision positioning of contact surface. Sliding friction was performed in pair Ni—Mo in air and lubricant CIATIM—201 under load of 82.3 kPa and linear velocity of 0.5 m/s. Number of working operating strokes was in the range of 1 − 36 × 103. Average volume temperature of the sample didn’t exceed 40˚C. Range of ferromagnetic resonance was registered by means of method described in paper [5]. Electronic and microscopic researches of nickel were carried out by the instrumentality of microscope ЭМВ—100 АК by means of thin foils “for transparency” at the Kharkov Technical University. Foils were obtained by means of single-sided electrolytic thinning of disks at the opposite side of the friction surface at the installation of jet-stream polishing, equipped with sensitive photodiode bridge, which makes it possible to control transparency of areas at the depth of ≈ 0.1 micrometers from the friction surface. Density of dislocations was determined using microphotographies by means of mutually perpendicular secants. Dislocation density data was obtained by means of averaging during examination of not less than five local areas in various grains.

3. Results and Discussion

Under friction loading dislocation structure develops in accordance with oscillation character. This was confirmed by electronic and microscopic researches, as well as by results of ferromagnetic resonance [1-4]. Periodicity of microstructure is associated with development of plastic and plastically destructed stages of deformation. Analysis of structural changes showed that two opposite processes with various degree of mutual exclusion take place in near-surface layer—hardening, which happens due to generation, motion and interaction between dislocations themselves and other defects of structure, and softening, which is associated with relaxation phenomena— annihilation of dislocations by partial phenomena of annihilation and formation of polygonal structures, development of microcracks and drain of dislocations onto the surface. But these relaxation mechanisms are of secondary importance. Researches showed [2] that reason due to which microstructure of nickel in certain time intervals (t—time of friction) after strong hardening becomes similar to that one of initial samples and then undergoes cold working, consists in selective peeling of dispersed layer of material. Further repetition of cyclic recurrence is associated with dispersion of underlying layers. This concept is confirmed by selective emission of wear products, which correspond to areas of cycloid decay, defined in [1].

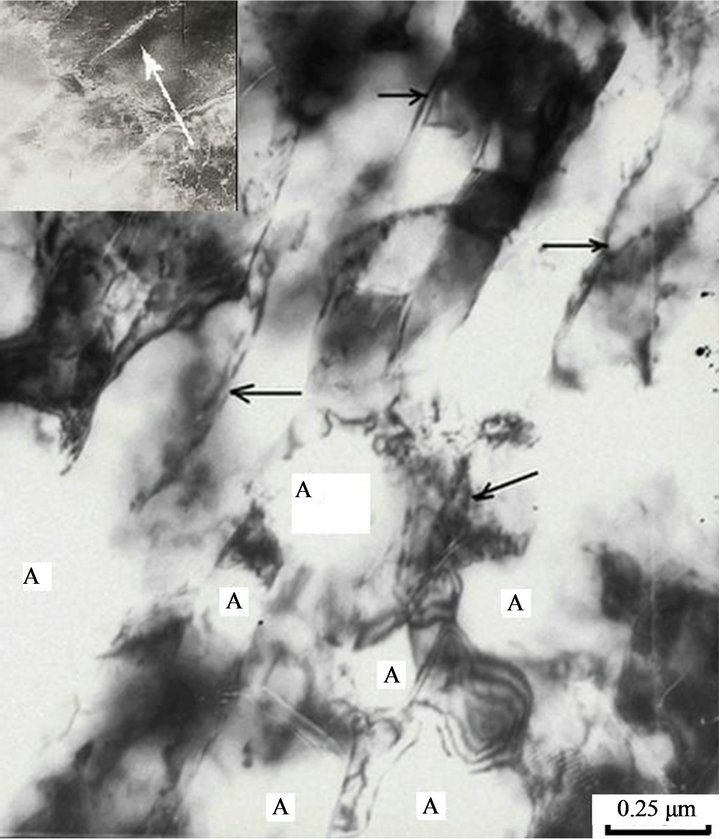

Significant grain refinement (up to ≈ 0.2 micrometers) and appearance of fine-grained polycrystalline phase with dimensions of 5 - 10 nm are characteristic for microstructure transformations of surface layer under friction. This close-meshed microstructure consisting of areas of high and low density of dislocations, which are quasiuniformly distributed in the volume of surface layer, is represented at the Figure 1. Observed nanocrystalline and submicrocrystalline fragments of microstructure (dislocation clusters) stipulate high degree of hardening and ensure certain plasticity of surface layer material due to certain length of grain boundaries. Areas with high density of defects contain aggregates of dislocation loops and dipoles with density of ρ ≈ 1015 M−2. High angular disorientation of cell boundaries, which can be compared to grain-boundary mismatch of ≈ 5˚ - 10˚, is characteristic for this fragmentary structure. This is confirmed by electron diffraction pattern of microstructure (Figure 1, insertion). Multiple reflections are located around diffraction rings, which are shown on this picture. This type of electron diffraction pattern is similar to that one of [6] and it confirms formation of grain-type fine-dispersed microstructure with large-angle disorientations.

Fine-dispersed structure and newly formed large-angle boundaries in the processes of plastic deformation and hardening are extremely important. Firstly, increase of boundary length causes increase of surface layer material plasticity under friction at the expense of grain-boundary slippage. Increased temperature of friction contact stimulates it. Secondly, microscopic elasticity limit increases significantly due to decrease of grain size [7], which results in lesser deformation of small grains before reaching this limit. Thirdly, grain boundaries function as good obstacle for propagation of fatigue cracks, as well as impede development of these cracks. That is why resistance to fatigue fracture increases together with decrease of grain size [7]. In accordance with [8] formation of grain-boundary, cracks happens under quite large ag-

Figure 1. Microstructure of submicroand nanocrystalline dimensions (t = 0.6 ks) Microdiffraction of microstructure.

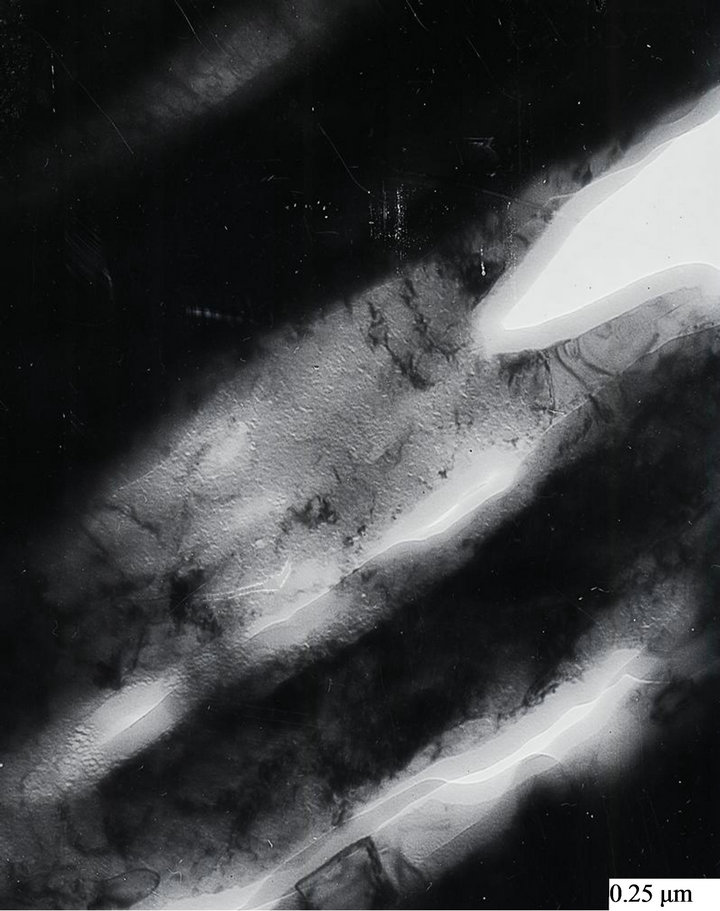

gregation of grain-boundary dislocations along the long plateau of grain boundary, which results in slight cracking along the boundaries of large-grain materials, which can be observed experimentally. Small rectilinear plateau holding small aggregates of grain-boundary dislocations, which quantity is not sufficient for formation and development of cracks, occur in small-grain structures due to multiple bends of boundaries. This phenomenon, to some extent, excludes grain-boundary cracking of small-grain material according to this mechanism. Uniform distribution of dislocation assemblies eliminates formation of local fracture nuclei. Thereby formation of fine-dispersed microstructure is one of the synergetic phenomena in surface layer under friction and that’s why metal surface extends its durability by forming those structures at a certain stage of friction loading. Refinement of coarsegrained structure and development of submicroscopic and microscopic sizes of grains are the results of intensive plastic deformation and decrease of active slip systems [9]. Tiny microcracks with characteristic dimensions of 0.01 micrometers (thickness) and 0.10 micrometers (length), which are not closed up, are formed at the stage of friction loading (t = 0.9 ks), constituting 12.5% of duration of surface layer destruction period (Figure 2, arrows). It appears that nature of these microcracks is associated with local bursts of temperature in the areas of actual contact, which leads to consolidation of vacant positions in micropores and subsequently to initiation of fracture nuclei. That is illustrated by consolidation of microvoids in the head of the series of consolidated microcracks (Figure 2, in the oval). There is the other version of formation of these microcracks, which is associated with development of surface shears and tears due to dislocation transformations. Observed local aggregates of dislocation loops and dipoles are the concentrators of strong elastic stresses. Under increase of density of these defects probability of their dissociation in aggregates into edge dislocations of opposite signs increases as well, and their exposure conditions shears and extrusions, which are concentrators of elastic stresses [10].

Germinative microcracks develop during further friction loading and under sufficient dimensions and quantities they consolidate into major crack by force of ductile fracture of material dividing them (Figure 2, insertion). That is seen in the Figure 2, where arrows show openended microcracks in substructure. Further transformation of substructure becomes apparent in occurrence of volumetric dislocation configurations in the form of bundles (Figure 3). Quantity of these formations of substructure per unit volume increases and they form grainoriented contours, which, in their turn, form slide bands. Availability of stable slide bands as areas of localized deformation determines further kinetic hardening and

Figure 2. Development of microcracks (arrows) (t = 0.9 ks), the inset (t = 5.4 ks).

Figure 3. Development of slide bands (t = 3.6 ks).

destruction of surface layer of metal under friction. Analysis of micrographs (Figure 4) shows that transformation of these bands into fragments of peculiar lamellar microstructure with chiselled boundaries takes place. According to interference images of these boundary interlayers (Figure 4, arrows) they may be identified with defects of crystal structure package, which cause elements of mismatch of crystal planes and great tensions. According to [11], total static and dynamic shift of atoms inside the slide band and along its borders by several times exceeds shifts in unstrained material. Localization of plastic deformation in boundary interlayers conditions development of microcracks along the slide bands due to weakening of interatomic bond (Figure 4, insertion). These processes become more intensive under increase of temperature [12]. Bands of lamellar structure appear after attainment of critical level of internal distortion of a grid at the stage of friction loading, constituting 60% - 70% of duration of surface layer destruction period (t = 5.4 ks). It’s likely that availability of localized layering and intensification of shear may result in development of major microcracks, which consolidate by means of destruction of material, which separates them (Figure 5). This process may be stimulated by ingress of a few observed twins. As far as twinning is associated with great shifts of crystal grid, occurring tensions may condition destruction in the form of cleavage.

Occurrence of multiple micropores inside blocks and

Figure 4. Transformation of slide bands into lamellar microstructure (t = 5.4 ks). Defects of packing (arrows). Development of microcracks.

Figure 5. Layer-specific failure of material (t = 13.4 ks).

along its borders (Figure 4, Position А) is associated with thermal cycling in the fields of friction contact, diffuse mobility of vacant positions and their coagulation. Under applied tensions micropores become concentrators of tensions and may cause transgranular failure.

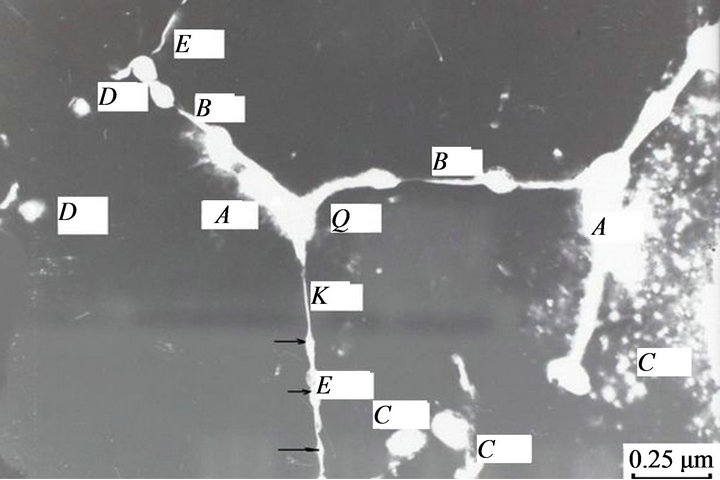

Elements of intercrystalline destruction were detected during tests (Figure 6). Grain boundaries are vulnerable to development of cracks and pores under combined loading and temperature of friction. Firstly, they are major places for drain of vacant positions and act as sources of these positions as well. It conditions development of pores during coagulation of vacant positions and increase of hollow spaces during drain of point defects onto its surface. Secondly, surface layer of metal may be under conditions close to yielding due to effect of combined loads and bursts of temperature in the areas of actual contact of mating surfaces. In this case sliding along grain boundaries stimulates mechanisms of intercrystalline destruction in connection with the fact that quantity of pores and microcracks develops in proportion to degree of slippage [13]. Thirdly, grain boundaries represent weakened areas of material strength.

At the stage of intensive destruction of material we may observe multiple micropores inside blocks (Figure 4, position А; Figure 6, Position С), as well as along boundaries (Figure 6, Position В, Е arrows). Coagulation of micropores forms hollows of coarse spherical shape (Figure 6, Position А). This process may be intensified by means of intergranular slipping. It is expected that under friction loading it is possible to reach critical concentration of local areas of overtension at the grain boundary, which are considered quite sufficient condition for grainboundary failure due to residual tensions resulting from anisotropy of thermal contraction-expansion [14].

Shear along grain boundaries leads to intensification of local deformation in pores, which results in dissipation of plastic fluidity energy into fracture-like shear cracks. This can explain occurrence of wedge-shaped microcracks at the bottom of pores near boundaries directed with their thin point to the nearest micro hollows (Figure 6, Position В). Observed directivity of destruction is conditioned by weakening of material strength along grain boundaries.

Function of micro hollows in a grain, which are located in close proximity to its boundary, still remains not enough clarified. It is said that pores, which are located in close proximity to incoherent boundaries, tend to vanish fast, as far as these boundaries act like sources and drains of vacant positions [15,16]. In accordance with our research pores co-exist with boundaries in close proximity to the latter (distance ≈ 0.1 micrometer), and moreover they initiate microscopic chips on these boundaries (Figure 6, Position D).

4. Conclusion

Oscillation behaviour of strength properties was discovered during research of kinetics of dislocation structure and processes of surface layer destruction (nickel) under friction loading. Each change cycle of dislocation density has its corresponding cycle of layer microdestruction. Strong grain refinement to nanocrystalline dimensions occurs under this loading together with quasiuniform distribution of grains along the volume of upper layer. During friction loading, this microstructure transforms into texture elements in the form of thin bundles, upon which it transforms into slide bands and peculiar lamellar struc-

Picture 6. intercrystalline failure of nickel (t = 113 ks).

ture. Microcracks develop along boundaries of these bands, upon which these microcracks consolidate into main cracks and form fragments of material destruction. Multiple micropores inside grains and along boundaries of these grains, as well as coagulation of pores, develop areas of transcrystalline and intercrystalline fracture. Friction loading leads to progressive loosening of upper layer of metal, associated with increase of quantity of fracture areas. At the stage of maximal dispersion this loosening in combination with developed brittleness conditions sharp increase of peeling mass of material in the form of whole layer. This process obtains avalanche-like nature and results in selective discharges of fracture products out of the area of friction contact.