1. Introduction

The prospects for seaborne trade are positive as expected compound annual growth rate between years 2018 and 2023 is put at 3.8% [1]. On the other hand, increase in amount of cargoes attracted to ports and facilitated handling at terminals, remain the goal of port managers [2]. Ports have significant influence on volume and conditions of trade as well as economic development of developing nations [3]. On the other hand speed in cargo handling and distribution impact on port efficiency and productivity. Effective and efficient utilization of cargo handling equipment in port operations contribute immensely to port productivity. In terms of services offered to vessels at the ports, Hart [4] posits that vessel’s turnround time is highly influenced by cargo handling performance. The application of automated systems and skilled labour in cargo handling operations therefore, are essential in ensuring timely operations, reduction in human errors, improvement in quality of service and reduced cost of operation [4]. Ports with modern berths and cargo handling equipment systems have the capacity to offer competitive international transport distribution services since they attract modern tonnage [5]. The overall cost of transportation from one port to another is influenced by speed with which cargo is handled. However, additional time spent in loading or discharging alternative ports’ cargo could translate to additional cost to port users such as shippers and shipowners. As noted by Branch [5], the failure of a port to modernize its berths and associated cargo-handling systems could encourage shipowners and shippers to use others. Accordingly, the need to eliminate inefficiencies in shipping logistics and improve operational efficiency in Nigerian ports necessitated port reforms involving concessioning of Nigerian seaports to private terminal operators in the year 2006 ( [6] [7] ). There have been some major investments in cargo handling equipment in the ports by private terminal operators. Anagor [8] notes that the investments in cargo handling equipment by the private terminal operators in Nigerian ports have resulted in improved cargo throughputs and vessel traffic.

1.1. The Research Problem

Optimal utilization of installed cargo handling capacity is a challenge facing most ports in Nigeria ( [9] [10] ) and this has had an adverse effect on port operation (i.e. ship and cargo operation). Cargo handling operations are critical to port efficiency. For example, if berth facilities are not fully and efficiently utilized, cargo handling rates would be low and operational cost per cargo will increase. In the same vein, underutilization of port’s cargo handling equipment could lead to port congestion which would adversely affect port’s patronage and revenue. The management of Nigerian ports attracted investments in cargo handling equipment through concession agreements with private port operators. However, improvements in cargo handling facilities due to new investments have not matched growth in cargo types and volumes spiked by the port reforms. Much of academic papers on port performance have concentrated on impacts of port reforms on ports cargo and vessel throughput growths. In this paper, we examine the utilization of existing and new facility upgrades and factors that impact their performance. The main objective of this paper is to assess the utilization of cargo handling facilities as well as significant factors impacting utilization of facilities in Nigerian ports.

1.2. Objectives of Study

The specific objectives of this study are as follows:

1) To determine the level of port facility utilization in the Nigerian ports.

2) To determine the speed of ship/cargo handling service (proxied by turnround times) offered to vessels at the berths.

3) To determine significant factors affecting utilization of cargo handling facilities in Nigerian ports.

The scope of this paper will be limited to evaluation of ship and cargo handling activities and constraining factors in Nigerian ports for the period between years 2006 to 2017.

2. Literature Review

Cargo Handling Equipment and Port Performance

There has been a remarkable change in cargo handling operation from the days of open stowage of merchandise to unitization of cargoes in form of containers, roll-on roll-off cargoes and palletization. These developments have necessitated the need for adoption of sophisticated alternative cargo handling methods and procedures [11]. The extent of handling operations at the quay and in transit sheds is determined by availability and capacity of cargo handling equipment [11] and how well the equipment is utilized. According to Meurn & Sauerbier [12] “the only time that a piece of material handling equipment is making money for its owner is when it is actually moving cargo”. Hence, increase in port revenue/profit is therefore tied to movement or handling of cargoes in an effective and efficient manner. Growth in World trade has however, significantly changed the mode in which ports operate. According to UNCTAD [13], as shipping began to specialize in vessels’ design and employed higher capacity; the port industry also began to respond to the challenges of serving these vessels. In assessing performance of these ports, four strategic dimensions are required namely: finance, operations, human resources and market [13]. Specifically, operations such as ship handling, cargo handling and service provisions apart from energy, environment and security, are considered the most commonly employed criteria in port performance assessment. For example, port performance requires a set of measures related to length of stay of vessels in port, storage/inland transport capacity and the rate of loading/unloading of cargoes [14]. Port performance indicators are measures of various aspects of port operation [15]. Many researchers also maintain that there should be adoption of a set of indicators for various type of cargo (such as break-bulk cargo, unitized cargo, liquid bulk and dry bulk cargo) since different facilities will be specifically used in handling these cargoes in port. Regardless of the type of cargo that is being handled in port, cargo handling capacity must be effective and efficient in order to achieve optimum cargo operational performance. Cargo handling equipment as a facilitating apparatus however, has been found to affect port performance [16]. For example, operational performance of cargo handling equipment has direct connection with berth operations, ship operation, transfer operation, storage operation and receipt/delivery operation [17]. Thus, improvement in port performance/produc- tivity cannot be achieved without productive cargo handling equipment. Investment in port facilities is therefore necessary for acquisition of modern cargo handling equipment to suit the growing technological development in ports and shipping [17]. However, failure to ensure that the acquired equipment is effectively and efficiently utilized will result in low equipment productivity and poor competitiveness of the ports ( [17] [18] ). The terminal operators in Nigerian ports claim that significant investments in form of high capacity gantry cranes, straddle carriers, expanded storage areas have been made. However, impacts of such investments on port operations can be measured using performance indicators. These include indicators of utilization of facilities and indicators of service to vessels and cargo owners (UNCTAD, 2006). These indicators according to UNCTAD (2006) are operationalized into the following metrics: ships waiting time, ships times at berth, berth occupancy and ships turnround times. The level of service obtained from deployment of ship and cargo handling facilities as well as constraining factors can also be assessed from opinion of port users. This approach dictates the framework for addressing the pertinent research questions raised in this paper. The combination of indicators of utilization, service and perceived factors impacting facility performance from port users could offer some insights into ports’ utilization of cargo handling facilities.

3. Research Methodology

The primary data in this research were collected from firms that provide shipping services and regularly conduct their operations in Nigerian seaports namely Apapa, Tincan, Onne ports, Rivers, Calabar and Delta ports. They comprise small, medium and large profile companies which by nature of their services and operations are major users of port facilities. The decision to survey them was made in the expectation that they could share their experience about operational status of cargo handling facilities as well challenges (if any) encountered in accessing them in the ports. To this end, copies of structured questionnaires were designed and sent to operations managers and supervisors in these firms. They were asked to rate their responses about perceived factors affecting utilization of cargo handling facilities in the ports. For further analyses, secondary data on ship and cargo throughputs, data on facilities in the terminals, cargo and ship operations at the berths were also collected. From the latter, it was possible to mathematically derive indicators of port facility utilization and service rates. These indicators enabled us to determine the extent of utilization of available facilities. Descriptive statistical models were employed to compute frequency distribution of responses from the sampled firms and mean (summaries) of ship and cargo throughputs. Classical tests of proportions were employed for testing hypotheses.

One Sample Test of Proportion

One sample proportion-test was employed to test for significant differences if any, in the proportion of respondents who agreed/disagreed on factors affecting cargo handling facility utilization in the ports. For example, to test the null hypothesis

that significant proportion of respondents agree that some factor is a determinant of port facility utilization, we set the null

against the alternative hypothesis:

. The Z-statistic for one sample population proportion, according to Aczel & Soundapandian [19] is calculated thus:

(1)

is the hypothesized proportion.

is calculated from the sample and

.

Where n is sample size from population of respondents.

Critical region:

(For a one-tailed test).

Decision Rule: Reject H0 if Zcal < 1.96 or Zcal > 1.96, if P-value < 0.05—the α- value.

Where 1.96 is the value of Z tabulated (Ztab) statistic (for a two tailed test).

The sample size (n) of population under study is 62. This figure is representative of port users in Nigeria’s ports industry.

4. Data Presentation and Analysis

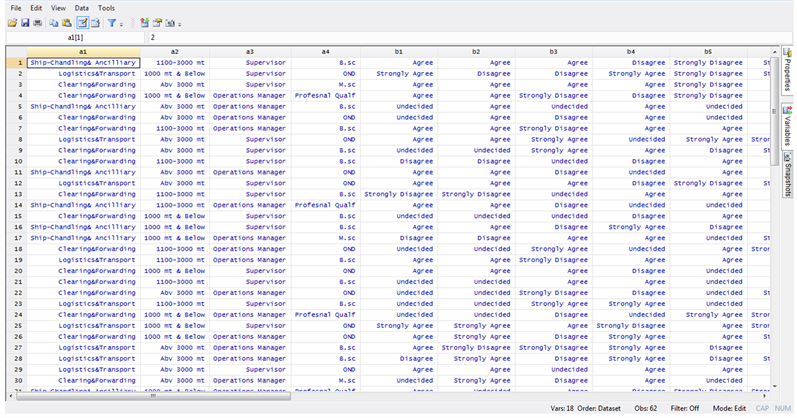

In Table 1, we present is the frequency distribution of the respondents’ profile. A total of sixty-two companies were sampled. About 42% of them offer Logistics and road haulage services to clients. Others are in the business of providing ship-chandelling (19%) and freight forwarding (39%) services. These companies are by the nature of their business major users of port services especially in the area of cargo handling. Thus, their opinion may reflect the state of cargo handling facilities and services offered in the seaports. The frequency distribution (in Table 1) also shows that low, medium and large scale companies (in terms of type of services offered) were adequately represented. About 42% of the companies handled on average, cargo volumes in excess of 3,000 metric tonnes per

Source: Author, data analysis based on field work.

annum. In terms of response rate, 53% of the persons who responded to the questionnaires were operation managers, while 47% of the others were supervisors. This result implies that only persons knowledgeable about utilization of port’s cargo handling facilities responded to copies of questionnaire administered.

Table 2(a) displays the types and corresponding number of mobile cargo handling plants in all the Nigerian ports before the terminal concessioning to private operators. Thus, from the table, it can be noted that out of total number of five hundred and fifty seven (557) plants and equipment available only two hundred and thirty two (232) were in useable condition as at end of year 2005. This figure represents 41.6% or less than fifty percent of what should be installed cargo handling capacity in the ports.

Table 2(b) shows the distribution of facilities brought by the terminal operators. It can be observed that these were marginal additions to movable facilities for quay and yard areas when contrasted with Table 2(a). Although, we do not have data up to periods covered in the study, however, it is evident that not much investment has been made by the private terminal operators.

In terms of other facilities and infrastructure available for ship and cargo handling in the ports, Table 3 shows that average number of berths, quay length, storage areas and draughts of the ports as at the year 2006 were 15, 677.66 m, 10,390 hectares and 9 m respectively. The data from Table 2(a) and Table 3 represent the state of infrastructure and facilities before the terminal concession policy in the year 2006.

However, after the port terminal reform policy in Nigeria, private operators assumed responsibility for terminal operations and provision of additional facilities and infrastructure. The concession reforms increased port patronage and induced surge in cargoes and vessels attracted to Nigerian ports. According to Table 4, between years 2006-2017, average volume of cargo and vessel throughputs handled

![]()

![]()

(a)Source: Abstracts of port statistics, 31st Dec. 2005.

(b)Source: Authors, Field work. Data for all ports in the study.

(a)

Table 2. (a): Distribution of cargo handling plants in Nig. ports before concession; (b): Distribution of quay & yard equip. in Nigerian ports for the Years 2007-2010.

at the ports increased to 1.19 million tonnes and 752 respectively. These figures represent marginal increments from base year 2006. A bar chart representation of the trends in cargo and ship traffic by ports can be seen in Figure 1(a) and Figure 1(b).

![]() (a)

(a)![]() (b)

(b)

Figure 1. (a) Distribution of cargo throughputs by ports (2006-2017); (b) Distribution of vessel throughputs (counts).

![]()

Table 3. Port’s cargo and vessel handling infrastructure in Nigerian ports.

Source: Abstracts of Port Statistics, 2006.

![]()

Table 4. Descriptive statistics of cargo and vessels throughputs in Nigerian ports (2006- 2017).

Source: Author, data analysis all ports in sample.

The port reform policy opened up Nigeria’s port sector to global competition. Both indigenous and many foreign terminal managing companies were as part of their concession agreements obligated to invest in terminal facilities to augment existing ones. The object was to improve ship and cargo handling speed and capacity utilization at the ports. Thus, for objective assessment of utilization and performance of port facilities against the backdrop of increased ship and cargo traffic, we analysed the following indicators shown in Table 5.

In Table 5, we note the average values (for all ports) of indicators of service to vessels namely: Average time ships spent awaiting berth (ATSAW), average time ships spent at berth (ATSAB) and average turnround time (AVTRT). The indicators of utilization include: berth occupancy and berth vacancy. Thus, from the values of these indicators shown, we observe that between the periods (2006 to 2017), vessels on average spent one and half days waiting to be allocated to berth for ship operation. Similarly, vessels spent average of four (4) days at berth while being worked on. The turnround time values imply that upon arrival, vessels spent average of six (6) days at the terminals for commencement and completion of ship operation. In terms of utilization of berthing facilities (and by extension other facilities deployed at the berths), the average occupancy rate of all berths by vessels was fourty-eight percent (48%) according to Table 5. As shown also in the table, berths were on average fifty-two percent (52%) vacant. It should be noted that the values of berth occupancies and vacancies are approximately the same. Ideally, the berth occupancy rate should be close to 100% denoting high berthing capacity utilization. In Table 6 and Figure 2, we show the indicators of performance disaggregated by ports under study.

According to ATSAW in Table 6, arriving vessel spent the following number of days before being allocated to berths in the following ports namely: Onne (0.23), Tincan (1.02), Delta (1.13), Calabar (1.39), Apapa (2.46) and Rivers (2.66) ports. In summary, ships spent extra days before being allocated to berths in Apapa and Rivers ports than in the other ports investigated. This outcome is indicative of unavailability of facilities needed to commence ship and cargo operations upon vessels calling at the ports. In terms of cargo handling speeds at the berths proxied by ATSAB, the same order was repeated except for Calabar port which now came before Delta port. This means that vessels that were positioned for service at berths spent less time (in days) in Onne (2.30), Calabar (2.72), and Tincan (3.46) ports than in the other ports namely Apapa (4.59), Delta (5.01) and Rivers (6.57) Although ATSAB depends on volume of cargo handled, however availability and better utilization of cargo handling facilities can fast track the handling process thereby reducing delays. In summary, the total time spent by vessels calling at Nigerian ports is represented by AVRT and from Table 6; calling vessels spent more time at Rivers (9 days), Apapa (7 days), Delta (6 days), Calabar (4.5 days), Tincan (4 days) and Onne (3 days) ports. If we denote berth

![]()

Figure 2. Distribution of berth utilization (%) in Nigerian ports (2006-2016).

![]()

Table 5. Descriptive statistics of indicators of service & utilization (2006-2016), all ports.

Source: Authors, data analysis.

![]()

Table 6. Descriptive statistics of indicators of service & utilization by ports.

Source: Data analysis; mean values in bold fonts, standard deviation in parenthesis.

occupancy rate (%) as indicative of extent of resource use for ship and cargo handling operations, then the following ports namely: Apapa (57.73%), Tincan (57.24%) and Rivers (55.54%) were more occupied than Onne (45.38%), Calabar (41.98%), and Delta (28.83%) ports. Thus, berths in Delta and Calabar ports were least utilized during the study period. This finding is consistent with comparatively higher berth vacancies of 65.77% (Delta) and 58.51% (Calabar) observed for these ports, see Figure 2.

In Figure 2, we note by inspection that berth vacancy rates were higher in Delta ports and Calabar ports in comparison to other ports. However, Apapa, Rivers and Tincan ports had comparatively higher berth occupancy rates.

Table 7 tabulates the results of responses of port users on questions regarding factors affecting utilization of cargo handling facilities at the seaports. Based on the tests of proportion results, the following factors were found to significantly affect utilization of cargo handling facilities: Obsolete plants and equipment, inadequate plants and infrastructure facilities, time consuming procedures in accessing facilities, poor port reform policy implementation. However, the respondents stated that more private sector investments could lead to increased level of cargo handling facilities and eventual high productivity at the ports.

Discussion of Findings

The analyses of data in the study provided evidence for inference on the status of ship and cargo handling infrastructure in Nigerian seaports since the reform

![]()

Table 7. Factors affecting utilization of cargo handling equipment in Nigeria Seaports.

Source: Authors computations. Z tabulated = 1.64 at α = 0.05 (single tail test).

policy implemented in the year 2006 by the Federal Government of Nigeria. Before the concession reforms, there were quay and yard cargo handling facilities in ports but only 41.6% of which were in operational condition. In terms of infrastructure, the average number of berths, quay length, storage areas and draughts of ports channel as at the year 2006 were 15.15, 677.66 m, 10,390 hectares and 9 m respectively. The status of these facilities and infrastructure had contributed to poor cargo handling performance uptil the point leading to the reforms. The private terminal operators as part of the concession agreements, invested in some facilities increasing marginally the number of quay and yard equipment though not adequate as seen in Table 2(b). However, the numbers of berths, quay aprons, and storage spaces have remained constant till date as Green field developments are yet to come on stream as at the time of this research. When viewed against the backdrop of spikes in vessel and cargo throughputs occasioned by the reforms (see Table 4), the persistent capacity problem in the ports becomes understandable. For example, we found in Table 6 that ships that called at Nigerian ports spent an average of one & half day before being allocated to berths. Again calling vessels spent 4 days at berths and at least 6 days before sailing outwards (average figures). This is indicative of delays often associated to limited facilities or poor utilization of same. There was also evidence of disparities in utilization of berthing facilities with Apapa and Tincan ports having more occupied berths while Delta ports and Calabar ports were least utilized. The respondents to the study observed that cargo and ship handling speed can be achieved if the terminal operators abide to their contractual obligations and invest more in facilities and infrastructure in the ports.

5. Conclusion

This study assessed the status and utilization of cargo handling facilities in Nigeria seaports. We found that only 46% of installed facilities were operational before the concession of terminals to private operators. The level of infrastructure has remained relatively constant due to limited waterfronts. In addition, Green field developments meant to augment existing infrastructure and facilities have not become operational as the time of the study. The terminal operators have invested in some quay and yard facilities, but this is only a marginal improvement on the existing facilities before the reform policy. The result is that ship and cargo operations at the ports have become less than optimal given the observed ship’s waiting time, time spent at berth and turnround times. Again some ports like Apapa and Tincan (Lagos based ports) were more utilized than Delta and Calabar ports. These outcomes have cost implications on both the cargo owners and ship operators. Thus, as observed by the port users, more commitments to investments are needed from the concessionaires for optimal productivity in ship and cargo operations and better utilization of facilities in the ports. There is need for active government monitoring to ensure that the private terminal operators fulfill their contractual obligations regarding facility upgrades in Nigeria ports. Again, the observed lopsided utilization of the sampled ports does not allow for global port user welfare gains. Thus, introduction of some form of administrative instrument may be necessary to divert some level of ship and cargo traffic away from Lagos based ports to Eastern based ones. Future studies should consider a more disaggregate study on impact of growth in cargo types (break-bulk, bulk, containerized) on cargo handling infrastructure facilities.

Appendix