Modeling of Solar Drying Economics Using Life Cycle Savings (L.C.S) Method ()

1. Introduction

The Sun is the largest source of energy in the solar system and it has the potential to supply all the energy requirement of the earth. Its economic potential for any country however depends on a specific location and locality. Solar energy is the most abundant energy source in the solar system. Despite the abundance of this energy, little use is being made of it in most part of the world. This could be attributed to the initial high cost of solar energy technologies, although on a life cycle costing basis, it is generally competitive with other energy technologies where a level playing field is provided and environmental cost is considered. Solar system applications are found in different facet of life. These include space heating, water heating, industrial/domestic cooking, drying of agricultural products, solar cooling and photovoltaic generation of electricity [1] .

1.1. Why Solar Drying?

The energy from the sun reaching the earth’s atmosphere amounts to about 1.395 kW/m2. This amount is only 1/1010 of the actual energy released by the sun. Out of this energy, 23% are used as source of hydrological cycles and photosynthesis in plants, 47% are absorbed by the atmosphere, land and ocean and are converted to long wave radiation (terrestrial radiation) and 30% are reflected and scattered back into space [2] . The use of solar dryers represents an alternative to the traditional open sun drying in developing countries. It satisfies several conditions such as fast processing, better quality of product, low energy demand and non-contaminating energy source. The main disadvantages of solar dryers are the limited time of solar radiation and the short season of harvesting of many agricultural products. Several designs of solar dryers have been proposed for use in developing countries. It has been concluded that to meet the increasing demands for food preservation in developing countries, simple, cheap but efficient solar dryers should be developed where forced convection and supplementary heat are applied [3] .

The drying potential in a cabinet drying bed can be employed when air is first dehumidified and then employed for drying of agricultural produce in an attached dryer. The proposed solar drying installation in this work is a coupling of solar collector, auxiliary energy source, and solar dryer of forced-convection type. The processes of mass and heat transfer in these units are simulated. The drying kinetics in a fixed-bed assumes a non-isothermal non-trace plug flow system with some basic variables [4] . One main reason for considering solar is due to its environmental friendliness, as it does not give out any form of environmental pollution, like smoke which characterizes the conventional fossil fuel heater. It also runs smoothly and quietly. This is because it has no mechanical moving part [5] . It also means that wear and tear in solar systems is relatively small, if not totally eliminated [4] . The environmental benefit of solar application also includes no global-warming potential associated as in conventional drying systems with fossils fuels with increasing fossil fuel prices opting for solar system in order to meet the heat energy requirement will save fuel costs and also, it is economically competitive on a life cycle costing basis [4] .

1.2. Significance of Life Cycle Savings Method

Solar energy devices and application are generally considered to be relatively new to the underdeveloped and developing nations of the world. Solar processes are generally characterized by high investment cost and low operating costs. Thus the basic economic problem is one comparing initial known investment with estimated future operating costs. Most solar energy processes require an auxiliary (i.e., conventional) energy source so that the system includes both solar and conventional equipment and the annual loads are met by a combination of the sources [2] . The Life Cycle Savings Method is a type of solar economic analysis of approach that takes the following into account 1) time value of money 2) detailed consideration of the complete range of costs 3) design criteria and variation in design factors.

1.3. Cost of Solar Energy Delivery

The cost of any energy delivering process includes all items of hardware and labour that are involved in installing the equipment, plus the operating expenses [6] . Factors that may be taken into consideration includes interest on borrowed money, property tax and income tax. Property tax and income tax may not be applicable in a country like Nigeria also the equipment resale value, maintenance insurance, fuel and other operating expenses should be taken into consideration.

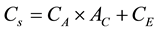

Installed cost of solar equipment can be shown to be sum of two terms [3] ;

1) CA = total area dependent cost (N)

2) CE = total cost of equipment which is independent of the collector area (N)

Therefore

where, Cs = total cost of installed solar energy equipment (N), Ac = collector area (m2)

The total area dependent cost, CA includes costs such as the purchase and installation of collector and a portion of storage cost. The area independent cost CE includes items like controls and bringing the construction erection equipment to site. Operating cost that are associated with solar process include cost of auxiliary energy, energy cost for operating fans/blower (this energy is often termed parasitic energy and should be minimized by careful design, extra insurance exists on solar equipment, maintenance etc.

1.4. Economic Figures of Merit

Some of the criteria proposed and used for evaluating and optimizing economics of solar energy systems are:

1.4.1. Least Cost Energy (LCE)

This is a reasonable figure of merit if solar energy is the only energy resource. The system with the least cost can be defined as that showing the minimum owing cost over the life of the system.

1.4.2. Life Cycle Cost (L.C.C.)

This is the sum of all the cost associated with an energy delivering system over its lifetime or over a selected period of analysis. This method includes inflation when estimating the future expenses.

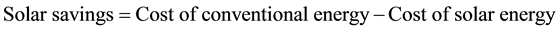

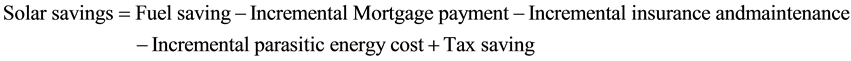

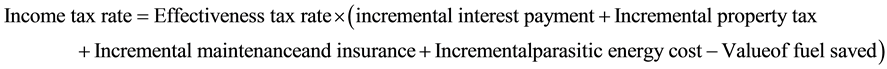

1.4.3. Life Cycle Savings (L.C.S)

It is also known as the net present worth and it is defined as the difference between the life cycle of conventional fuel (only system and life cycle cost of the solar plus auxiliary energy system).

1.4.4. Annualized Life Cycle Cost (ALCC)

This is the average yearly outflow of money (cash flow).

1.4.5. Pay-Back Time

This have many definitions but in this paper, it is taken to be the time needed for the cumulative savings to equal the total initial investment, i.e., how long it takes to get investment back by saving fuel.

2. Methodology Solar System Cost Analysis

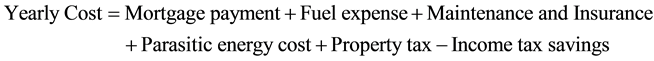

In the mathematical model formed, the annual cost for both solar and non-solar system to meet energy need can be expressed as [2] ;

(1)

(1)

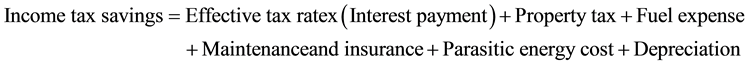

For income producing installation [2] ;

(2)

(2)

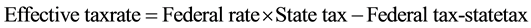

(3)

(3)

(4)

(4)

With this savings concept, it is only necessary to estimate the incremental cost of installing solar system because the solar system may have some equipment which is also common to the conventional non solar system. For example the auxiliary furnace and much of the duct work or plumbing in solar system are often the same as would be for a non-solar system. Therefore, solar savings can be rewritten as expressed below [2] ;

(5)

(5)

For income producing system [2] ;

(6)

(6)

Fuel saved is a negative tax deduction since a business already deducts fuel expenses, therefore, value of fuel saved is a taxable income [2] .

2.1. Discounting of Future Cost: Inflation

An approach to solar process economics is to use life cycle cost method that takes into account all future costs. The method provides a means of comparison of future costs with present costs. This can be done by discounting all anticipated costs to the common basis of present worth (or present value), that is, what would have been invested today, at the best alternative investment rate to have the funds available in the future to meet all anticipated expenses. The reason that cash flow must be discounted lies in the time value of money [2] .

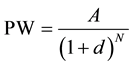

2.1.1. Present Worth (PW)

The relationship for determining the present worth of an amount “A” needed “N” (usually years) in future, with a market discount rate of “d” (present per time period) is [2] ;

(7)

(7)

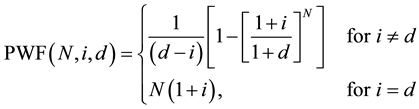

2.1.2. Present Worth Factor (PWF)

If obligation reoccurs each year and inflate at a rate “i” per period, a present worth factor, PWF, of “N” such payment can be found by using the following relationship [7] ;

(8)

(8)

2.2. The Computer Program

The computer program makes use of the metrological data to design the solar collector. The program attempts to obtain a collector area which is capable of supplying the whole annual air heating load based on the size of a single solar module which is also a variable. Although the attainment of this state might not be practically possible as there will always be some period of cloudiness, but as the number of solar modules increases the annual fraction by solar also increases. The economic analysis is performed using the life cycle savings method. By considering the life cycle saving of the different collector size (or area) and their corresponding annual solar fraction by solar, the economically optimum collector size can therefore be selected. If reducing cost is to be considered, the optimum collector is often the one with the highest solar savings. The database contains the global radiation and the extraterrestrial solar radiation, average sunshine hours, and average relative humidity of 10 different locations in Nigeria. The database also contains properties of air as the working fluid and also that of steam. Other data in the data base are monthly averaged ambient temperature of each location, the geographical position and their monthly averaged wind speed. The database also contains data on the materials that could be used in constructing the solar collector, thereby providing the users with a choice of materials and hence cost flexibility. The program gives room for adding, deleting or editing the data concerning any location. However, additional materials which could be used in constructing the collector can also be added to the database but with the required material properties.

3. Results and Discussions

The simulation software was used for investigation with different thermo properties of air as fluid, locations etc., and results were obtained for 50,000 kg of agricultural produce per month. Table 1 presents the input data/para- meters needed for simulation of the selected locations i.e. Ibadan, except that the location name needs to be edited each time there is change in location. The input data are kept in input data file within the computer program. Table 2 shows how monthly heat load and the total fraction of 0.667 supplied by solar energy varies in a year for Ibadan location. Table 3 presents the input necessary for the cost analysis for the three locations since cost is cost everywhere except cost differ in value. Table 4 gives the analysis of solar savings of 1,146,112,170 of currency unit, as to which was made through solar installation for twenty years in Ibadan location while given room for the many economic figures of merit. Table 5 is another input parameter table but know for Kano location. Table 6 shows the same thing as Table 2 but with 0.88 as the fraction of solar energy supplied know for Kano location. However Table 7 does the same as Table 3 with solar worth of savings of 17,764,928.49 of currency unit, for Kano. Table 8 does the same as Table 1 and Table 9 has 0.558 as the fraction of energy supplied by solar and Table 10 presents the solar savings over 20 years as 9,269,740.77 of currency unit, for Port Harcourt location. Both tables and figures shows that the overall cost of solar equipment and installation for locations with higher sunshine hours are lesser while the solar savings increases with time but later remain stable after some years. Most agricultural produce exhibit about 25% - 30% initial moisture content (wet-basis) before they are solar dried [8] . When decreasing initial moisture content, i.e. 50%, 40%, 30%, 20% (wet basis) were used in the simulation, the fraction of energy supplied by solar increased gradually. The required collector area in, m2, consequently reduced, and hence a reduction in the overall solar dryer cost [8] . The lower the initial moisture content, of the produce, the higher the energy supplied by solar, and also the higher the fraction of energy

![]()

Table 1. Data/parameters input for Ibadan location.

![]()

Table 2. Analysis of solar load output for Ibadan location.

![]()

Table 3. Cost analysis input parameters for Ibadan, Kano and Port Harcourt location.

supplied by solar. Consequently, the much lower the initial moisture content the smaller the initial cost of investment, the shorter the pay-back time (years), and the lower the collector area required in m2 with all other parameters kept constant.

For Ibadan location as shown in Tables 1-4, with 50,000 kg/month of agricultural produce the average sunshine hours per month is about 159.8 hours. Therefore the drying rate will be 313 kg per hour. For Kano location as shown in Tables 5-7, with the same 50,000 kg per month of agricultural produce, the average sunshine hours

![]()

Table 4. Solar savings over 20 years for Ibadan location.

![]()

![]()

Table 5. Data input for Kano location.

![]()

Table 6. Solar load analysis output for Kano location.

![]()

![]()

Table 7. Solar savings over 20 years for Kano location.

![]()

Table 8. Data Input for Port Harcourt location.

![]()

Table 9. Analysis of solar load output for Port Harcourt location.

![]()

Table 10. Solar savings over 20 years for Port Harcourt location.

per month is about 261.7 hours therefore the drying rate will be 191 kg per hour. For Port Harcourt location as shown in Tables 8-10 with the same 50,000 kg produce the average sunshine hours per month is about 118 hours. Therefore the drying rate will be 424.3 kg per hour. A close observation of the drying rate of Ibadan, Kano and Port Harcourt of the produce revealed close and neighbouring values. Hence, a better way is to fix the drying rate in kg/hr. or kg/s., and calculate the amount that can be dried in each location. However, the large difference between any industrial solar dryer located at Ibadan, Kano and Port Harcourt will be the initial investment cost of equipment (to include solar collectors unit area cost), the solar savings for a given period of time and the pay-back period. The total cost which include, the installation cost, the equipment cost and the operating costs and maintenance cost at Ibadan and Port Harcourt will surely be on the high side when compared to that in Kano, hence relative advantage at locations with high average sunshine hours per day to those with lesser or lower average sunshine hours per day. However, a better solar saving could be achieved with lower inflation and interest rates. Figure 1, Figure 2 and Figure 3 show that Ibadan location has moderate solar fraction and

![]()

Figure 1. Annual solar fraction against collector area for Ibadan location.

![]()

Figure 2. Monthly solar radiation on collector against month of the year for Ibadan location.

distribution when compared to Kano location in Figures 4-6, but for Port Harcourt from Figures 7-9 with lower solar fraction both annually and monthly. Also affecting is the air flow rate required for drying, as it was revealed during simulation, that higher air flow rates, keeping other things constant, means increase in the annual solar fraction but for larger fan/blower and consequently cost of purchase [1] . The simulation iteration stops when 1) The number of solar modules obtained can fully supply the energy needed for drying 2) when the additional energy needed is less than 1/100th of the original energy supplied by the lead solar module. The simulation was done with input that represents industrial applications.

![]()

Figure 3. Solar savings against collector area for Ibadan location.

![]()

Figure 4. Annual solar fraction against collector area for Kano location.

Cost Analysis

In developing countries like Nigeria, items like mortgage interest rate, down payment and the likes, sounds unrealistic, hence the cost analysis is recommended to be adapted. The CA and CE are area dependent cost and area

![]()

Figure 5. Monthly solar radiation on collector against month of the year for Kano location.

![]()

Figure 6. Solar savings against collector area for Kano location.

independent cost respectively and they contribute to the overall cost of the installation. Based on simulation experience, CA ≈ nCE and for industrial set up it was assumed that, n = 3. If a smaller initial moisture content is used, the collector area required for a solar fraction supply will be smaller and hence larger CA/CE. Smaller CE will surely reduce Cost, Cs. Therefore the larger the ratio of CA/CE, the more reduced “Cs” and hence, higher solar savings.

![]()

Figure 7. Annual solar fraction against collector area for Port Harcourt location.

![]()

Figure 8. Monthly solar radiation on collector against month of the year for Port Harcourt location.

![]()

Figure 9. Solar savings against collector area for Port Harcourt location.

4. Recommendations

The selection of other materials for use in the design should also be based on their availability and affordability because nobody will want to buy any equipment that is too expensive and for which spare parts are not locally available. To help in performing economic analysis using this software, prices of solar air heating systems of different configurations can be obtained on the internet sites of international vendors and manufacturers. Though varieties of economic figures of merit like payback times, cash flow etc., have been proposed and applied but the life cycle costing method is sufficiently the most inclusive since it take into account any level of detail the user wishes to include even, the dynamic nature of time value of money and hence recommended. The kinetics of moisture within the agricultural produce had not been dealt with in this paper.

5. Conclusion

Pre-investment, investment and operating cost that may be attached with industrial solar drying processes are actually functions of different meteorological data. These data are the essentials of optimum profit when the application of Solar drying equipment becomes pragmatically imperative. Although there are many values of solar collector that could easily support profitability but the optimal collector area needs to be examined and appropriately applied. However, the study revealed that solar collector area of 85.46 m2, 80.71 m2 and 75.96 m2 supplied about 67%, 88% and 55.8% of the annual energy needed which are the simulated optimum solar energy value with payback period of 8 years, 6 years and 8 years and also salvage value of 265,123.06, 250,880 and 236,636.91 for Ibadan, Kano and Port-Harcourt locations respectively. Though many solar economic figures of merits are available but larger number of those methods are designed to evaluate fuel payment for an alternative or conventional process and energy supply.

NOTES

*Corresponding author.