Performance Evaluation of Heat Exchangers in OTEC Using Ammonia/Water Mixture as Working Fluid ()

1. Introduction

Energy and environmental problems are becoming more critical; the development of natural energy is desired. Ocean thermal energy conversion (OTEC) using temperature differences between warm surface seawater and cold deep seawater can supply stable electrical power [1] integrated into a variety of applications, such as seawater desalination, residential cooling, and aquaculture [2-6]. In addition, the beneficial effects of OTEC systems on global warming and energy shortage problems seem promising. Oceans have a huge amount of stored thermal energy, although, the energy density is low. As an OTEC system operates in conditions of small temperature differences, an appropriate working fluid must have a low boiling point if it is to be used in a closed-cycle OTEC. The OTEC system requires warm water, cold seawater, and a working fluid pump power; the ratio of the warm and cold water pump power to output power is comparatively higher than that of conventional fossil power plants.

Research is continuing on the Rankine cycle which is the conventional closed-cycle process exploiting lowboiling-point working fluids such as ammonia. Using a pure substance as working fluid, the thermal efficiency of the OTEC cycle increases with decreasing irreversible losses in the cycle or increasing effective temperature difference, specifically the difference between evaporating and condensing temperatures of the working fluid. For that reason, it is necessary to decrease energy losses in the heat exchangers, namely to decrease the temperature difference between seawater and working fluid. This is done by increasing the heat transfer area or the overall heat transfer coefficient. Using non-azeotropic mixtures such as ammonia/water as working fluids in the OTEC cycle was proposed by Kalina in 1982 [7]. Uehara et al. [8] indicated that reducing the irreversible losses in heat exchangers using non-azeotropic mixtures leads to improvements in the thermal efficiency of the cycle. Furthermore, they focused on the Kalina cycle, and presented a new cycle using the ammonia/water mixture [9]. Several theoretical and experimental investigations have reported that thermal efficiency of such Kalina cycles is higher than that of the Rankine cycle using pure ammonia [10-15]. Other studies have reported that the effective temperature difference and heat transfer coefficient decrease with changes in concentration in the boundary layer during evaporation and condensation [16-18]. Previous studies have investigated the operating conditions and equipment of an experimental apparatus using ammonia/water mixtures to improve system performance. Ikegami et al. [19] performed experiments to investigate the influence of system performance on ammonia concentration in the mixture. The experiments were performed to assess the stability of the ammonia/water mixture power cycle [20]. The results from these experiments showed that it is critically important to enhance the performance of the condenser in increasing the performance of the total OTEC system. Furthermore, the characteristics of the ammonia/water mixture cycle have not as yet been thoroughly clarified experimentally.

To enhance the ammonia/water mixture cycle, clarification of the heat exchanger performance is extremely important. The traditional and effectual evaluation method of heat exchanger performance is the logarithmic mean temperature difference (LMTD) method but application of this method is limited to heat exchangers using working fluids having constant heat transfer coefficient and thermal properties. The generalized mean temperature difference (GMTD) method however enables variations in thermal properties in heat exchange processes to be included. Utamura et al. [21] first proposed the GMTD method, and applied it to evaluate the heat exchange process between hot water and supercritical carbon dioxide as a working fluid. As a result, validity of the GMTD method was proved. The GMTD is believed applicable in the evaluation of heat exchangers using ammonia/water although properties of the mixture are quite distinct. It is not clear whether the GMTD method is valid for heat exchangers using non-azeotropic mixtures as working fluid.

In this paper, clarification is obtained on the characteristics of heat exchanger using ammonia/water mixtures in improving cycle performance, achieved with the available methods of evaluation heat exchangers. A comparison is made between LMTD and the recently developed GMTD calculation methods as performed on the heat exchanger using ammonia/water mixture and the applicability of the GMTD method is assessed.

2. Temperature Change in Heat Exchangers with Ammonia/Water Mixture

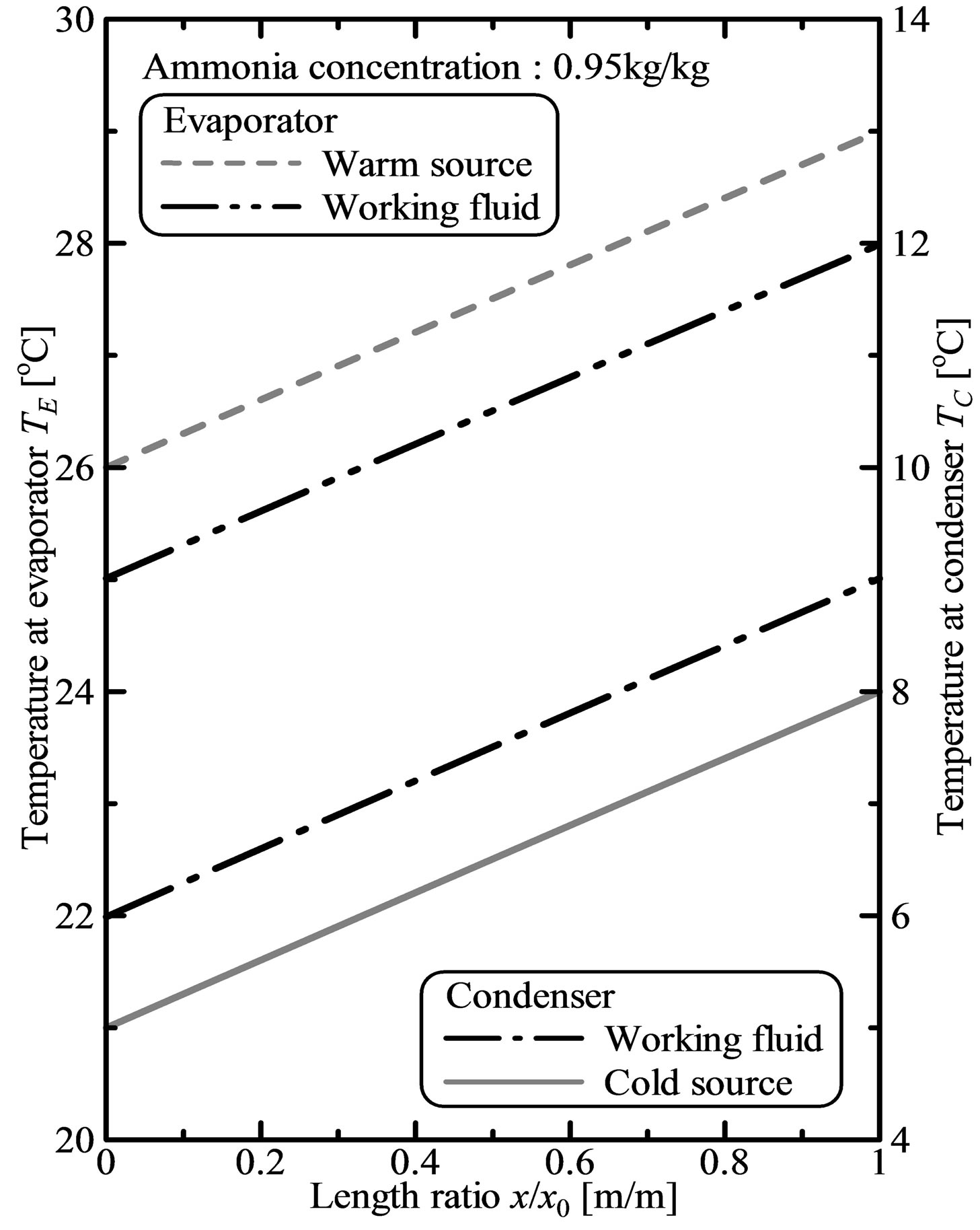

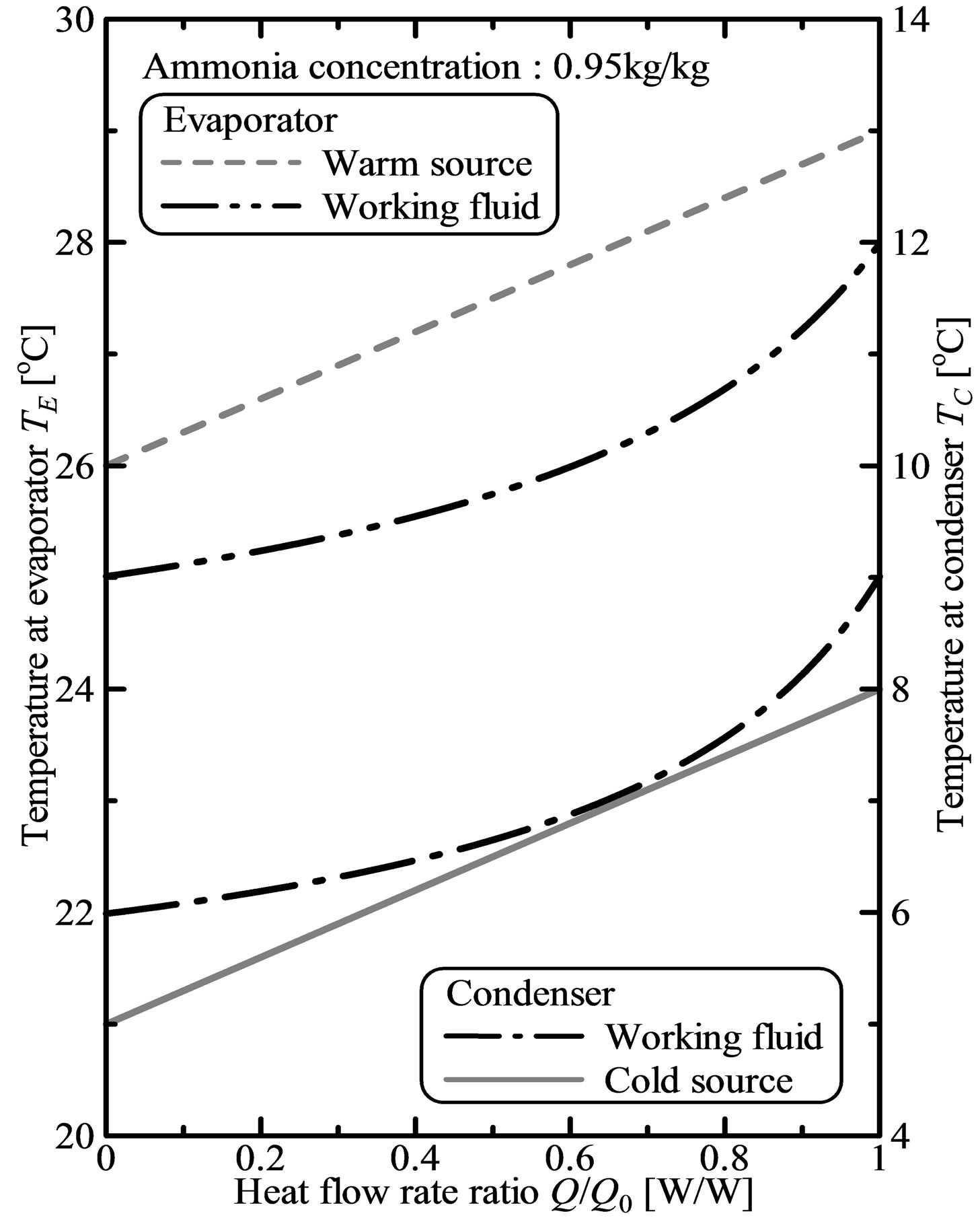

In Figures 1(a) and (b), the distributions of the fluid temperature within the heat exchanger is given as a function of distance (Δx) and heat flow rate (ΔQ), respectively. The temperature variation of the ammonia/water mixture changes in the heat exchanger owing to the large difference between its boiling point and its dew point. Consequently, an increase in available exergy of the system is expected with this mixture as working fluid. From Figure 1(a), the improvement in heat transfer performance and the ratios of the working fluid temperature to the heat source temperature in the evaporator and to the cold In Figures 1(a) and (b), the distributions of the fluid

(a)

(a) (b)

(b)

Figure 1. Temperature change in heat exchangers. Relationships between temperature and (a) length ratio and (b) heatflow-rate ratio for evaporator and condenser.

temperature within the heat exchanger is given as a function of distance (Δx) and heat flow rate (ΔQ), respectively. The temperature variation of the ammonia/water mixture changes in the heat exchanger owing to the large difference between its boiling point and its dew point. Consequently, an increase in available exergy of the system is expected with this mixture as working fluid. From Figure 1(a), the improvement in heat transfer performance and the ratios of the working fluid temperature to the heat source temperature in the evaporator and to the cold source temperature in the condenser are important when considering enhancing cycle performance. From Figure 1(b), the working fluid temperature is a convex curve of the heat flow rate. The working fluid temperature approaches the warm water temperature in the inlet and outlet of evaporator but approaches the cold water temperature in the middle of the condenser. The pinchpoint in particular is not well determined by the inlet and outlet temperatures in condenser. In addition, the traditional evaluation method underestimates heat transfer performance. Hence, the GMTD method, which accounts for the variation in the thermal properties, has been introduced for this performance evaluation. In contrast, for a pure ammonia working fluid, temperatures are constant in these heat exchangers because the thermal properties are stable.

2.1. Traditional Evaluation Method

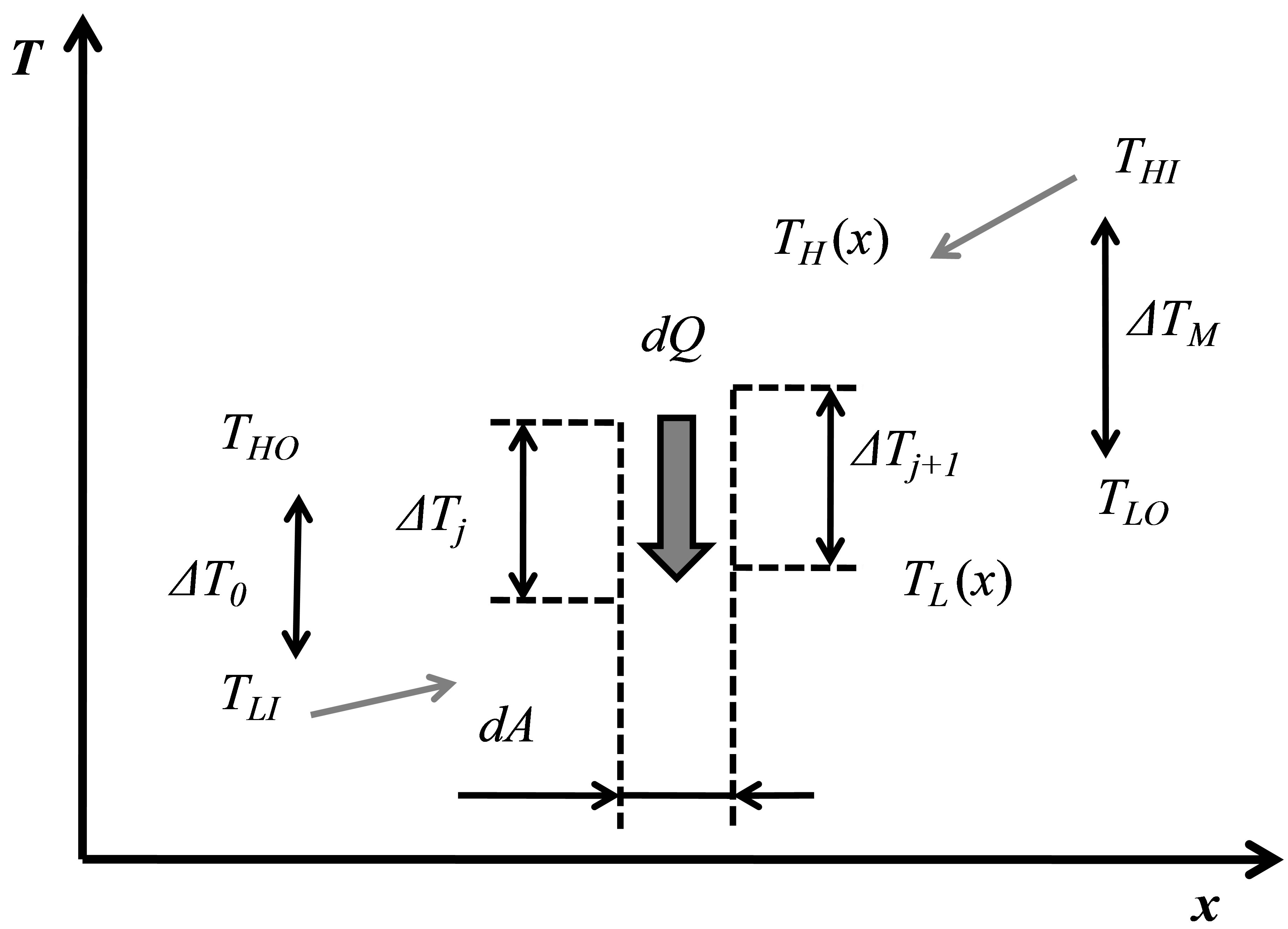

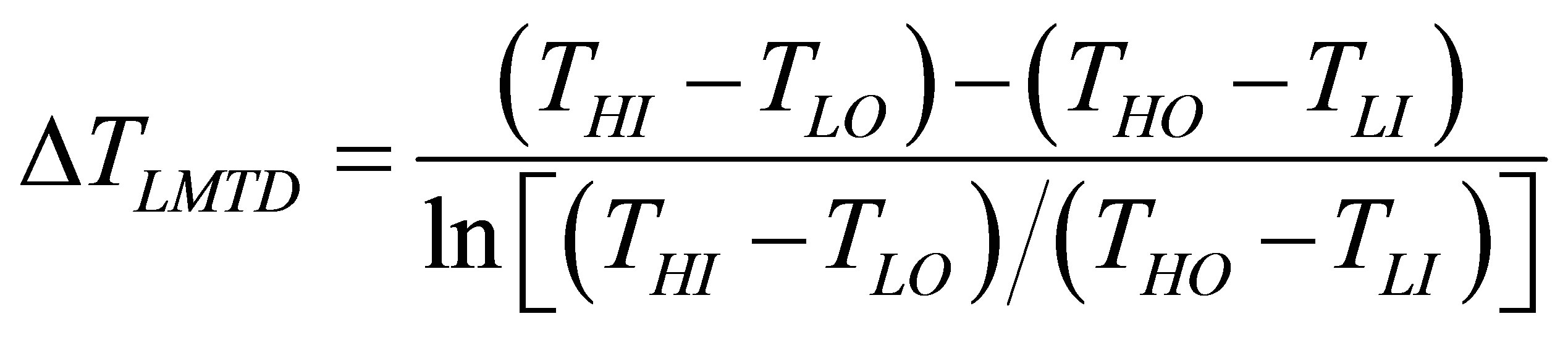

The LMTD method has traditionally been used to evaluate the temperature difference between the heat source and the working fluid in a heat exchanger. The LMTD method is used only when the thermophysical properties of the local fluid in the heat exchanger and the overall heat transfer coefficient are constant. Hence, the fluid in the heat exchanger undergoes temperature changes as shown in Figure 2 with the horizontal axis conceptually representing the length. The LMTD method is expressed as follows:

Figure 2. Fluid temperatures in the counter-flow heat.

. (1)

. (1)

where THI, THO, TLI and TLO are the high and the low temperature fluids heat exchanger inlet and outlet temperatures.

2.2. Innovated Evaluation Method

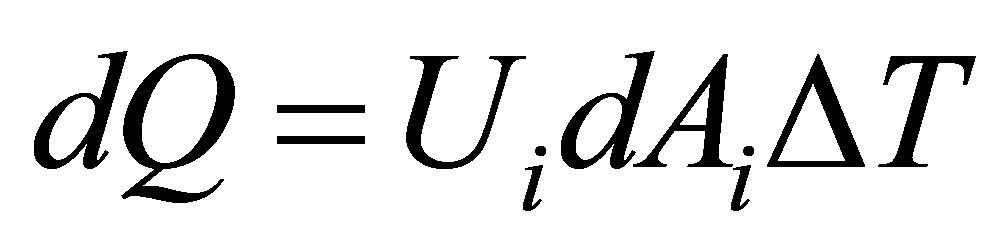

For an improved evaluation, it is necessary to consider variations in the thermophysical properties that better reflect conditions within actual heat exchangers. Therefore, the calculation results of LMTD are compared with those of GMTD and assessed. Using Figure 2, the heat flow rate for the heat exchanger, dQ from x to x + dx, is calculated using:

. (2)

. (2)

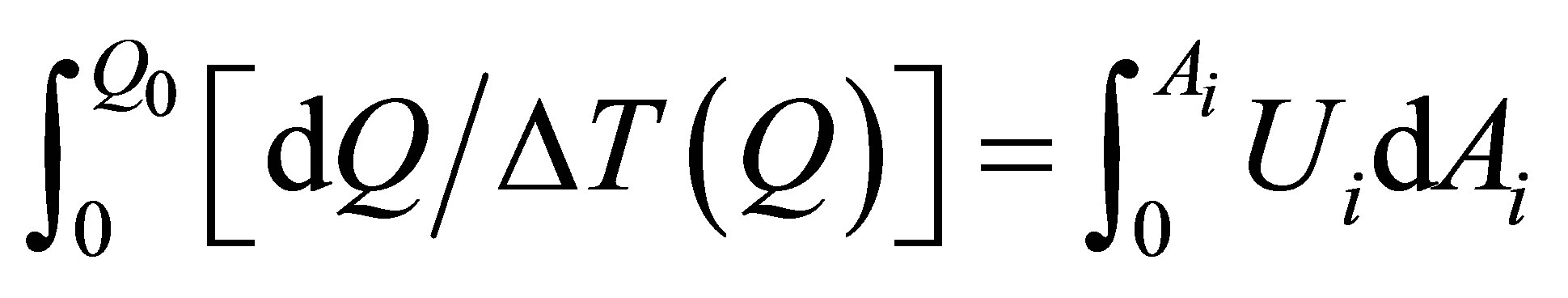

where Ui represents the overall heat transfer coefficient for the ith segment, mass flow rate of the warm or cold source, dAi is the heat transfer surface area, and ΔT is the temperature difference between highand low-temperature fluids. Integrating equation over all segments of the exchanger yields

. (3)

. (3)

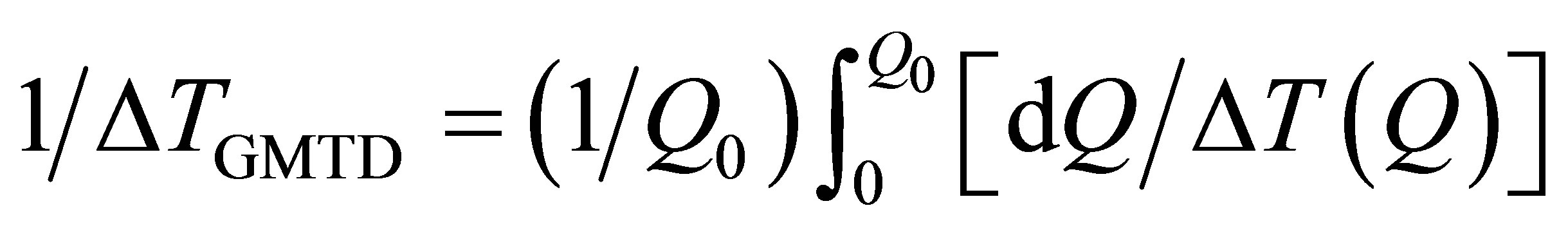

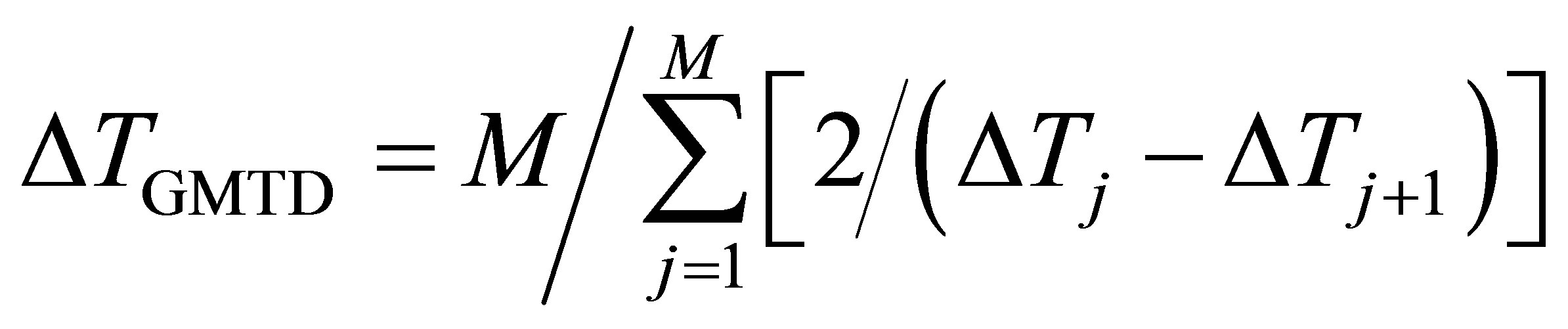

Then, the GMTD ΔTGMTD is defined as follows [21]:

. (4)

. (4)

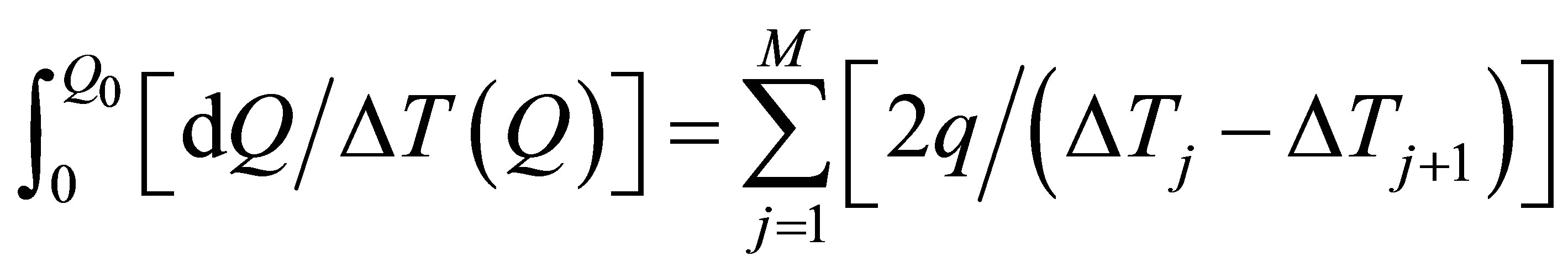

The temperature integral is approximated as:

. (5)

. (5)

Therefore, the GMTD is calculated by:

. (6)

. (6)

3. Comparison between Pure Ammonia and Ammonia/Water Mixture

Figure 3 shows the correlation between GMTD and LMTD for the evaporator and the condenser calculated for both pure ammonia and ammonia/water mixture as working fluid. The evaporator and the condenser are counter-flow-type heat exchangers; both warm and cold sources are water; for the warm water, the inlet temperature is 28˚C, and the outlet temperature is 25˚C; for the cold water, the inlet temperature is 5˚C, and the outlet temperature is 8˚C. For pure ammonia, the evaporation temperature varied from 27.5˚C to 26.0˚C; the condensation temperature varied from 5.5˚C to 7.0˚C. For the ammonia/water mixture, the temperature at the evaporator inlet varied from 27.5˚C to 26.0˚C, and at the evaporator