Recovery and Use of Blast Furnace Slag in the Field of Road Construction in Algeria ()

1. Introduction

Nowadays, the elimination of various waste products from different industries is a serious problem. These materials have an environmental pollution in the nearby community in recent years; applications of industrial wastes have been taken into account in road construction with a great interest in many industrialized and developing countries [1]. The use of these materials in the construction of roads is a decision based on technical, economical and ecological criteria [2-5].

To preserve the environment, natural resources, encourage recycling, we base our present study on the development of blast-furnace slag in the road. Construction and road maintenance require huge amounts of aggregates, rather restrictive specification road that only certain categories of materials are commonly used [6,7].

These industrial wastes represent a significant percentage of the industrial landfill. The valuation of these products has a twofold effect: it avoids the landfill (risk of environmental pollution) and limits the use of natural aggregates (natural resource depletion and fragmentation of the landscape ecosystem).

The recovery of blast furnaces slag is not currently subjected to national rules regarding the use and protection of the environment. Moreover, the public works management is conducting a national action plan to encourage research in this direction [8]. This stems partly from the long experience in the use of these slags in road work, and using that to date has not revealed any adverse impact on the ecological system [9].

Slag is a by-product of iron making in blast furnace steel mills. For a cubic meter of molten metal 280 to 340 kg of milk is produced in modern blast furnaces. In Algeria the annual production of milk is estimated at 500,000 tones finding only a few applications [10,11]. In cement, granulated slag is only used as additions to Portland cement, obtained by rapid cooling to keep the glassy state. Cons by crystallized slag is obtained by slow cooling in air, gives a rock hard, angular, after crushing and screening, can be used as aggregate in concrete pavement foundation materials, embankment, asphalt [12]. So the metal industry-steel is the largest producer of waste that often has a negative image and poses a disposal problem and nuisance to the environment.

The concern of industry is to get rid of the waste or use them in new forms in the materials of construction industry and thus find a new life and save natural resources and protect the environment.

This study is an attempt to use the blast furnace slag in road construction or in the sub grade or in the wearing course (the coats). The study involves the use in the subgrade of natural materials and careers available in the vicinity of the site, the slag is introduced with a percentage and the result of successive Proctor determining the optimal percentage of dairy used. For asphalt mixture used in proportions, aggregate and binder to wait for better mechanical characteristics is selected by introducing a percentage of slag in the formulation, while retaining single type of bitumen for the first time.

2. Subgrad

To construct the sub-grad, natural materials and of career available in the vicinity of the building site are used. The slag is introduced with a successive percentage. The results of Proctor tests give the optimal percentage of the used slag [13].

2.1. Materials

The used materials in the present study are: a crushed material from the career SOREST, located at Ouedi Sagan (Mila) in eastern Algeria; a roller material fras; artificial materials as the granulated slag and crystallized slag, coming from the iron and steel plant of El-Hadjar (Annaba) in eastern Algeria and a ground of the type (tuff-limestone).

2.2. Deduction and Sampling

The tests have been carried out at the Materials Laboratory of Civil Engineering at Constantine University. Sampling carried out on heaps for the case of granular materials, or on site for tuff while complying with the regulations relating to the deduction and sampling [14].

2.3. Classification Tests

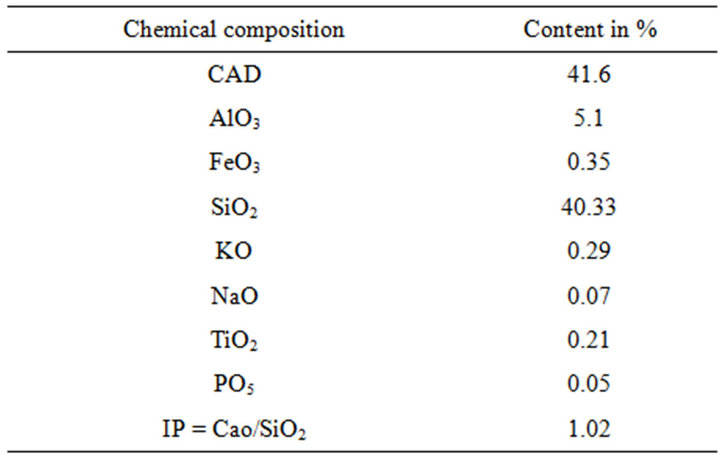

Chemical composition of the slag, depends on the iron bearing load of the blast furnace and is adjusted in order to allow the elimination of the harmful elements to the working of the blast furnace and the quality of the cast iron [15] (Tables 1 and 2).

The values of the index of alkalinity of both slags are of 1.12. It means that they are of basic nature. Table 3 shows the initial water content and the density of various materials.

It is noted well that the water content is high in the case of granulated slag. This is due to its heat balance which takes into account the variation of enthalpy, when the slag passes from 1450˚C to 100˚C. About 600 litres of water is needed to ensure its cooling and its dispersion.

Table 1. Chemical composition of the crystallized slag.

Table 2. Chemical composition of the granulated slag.

Table 3. Initial water content and densities of materials.

2.4. Mechanical Tests

The parameters of mechanical behaviour are considered with an aim of distinguishing the materials whose granular fraction is likely to resist the traffic of those which are likely to split up. Table 4 shows different mechanical properties of various materials.

It is noted that the granulated slag has a water natural content (Wn = 10.2%) and optimum water (Wop = 14.6%). However, the crystallized slag presents (Wn = 0.6% and Wop = 2.5%), which does not need a great quantity of water for their compaction.

Table 5 shows the optimum water and optimum density couples for various materials, obtained from Proctor